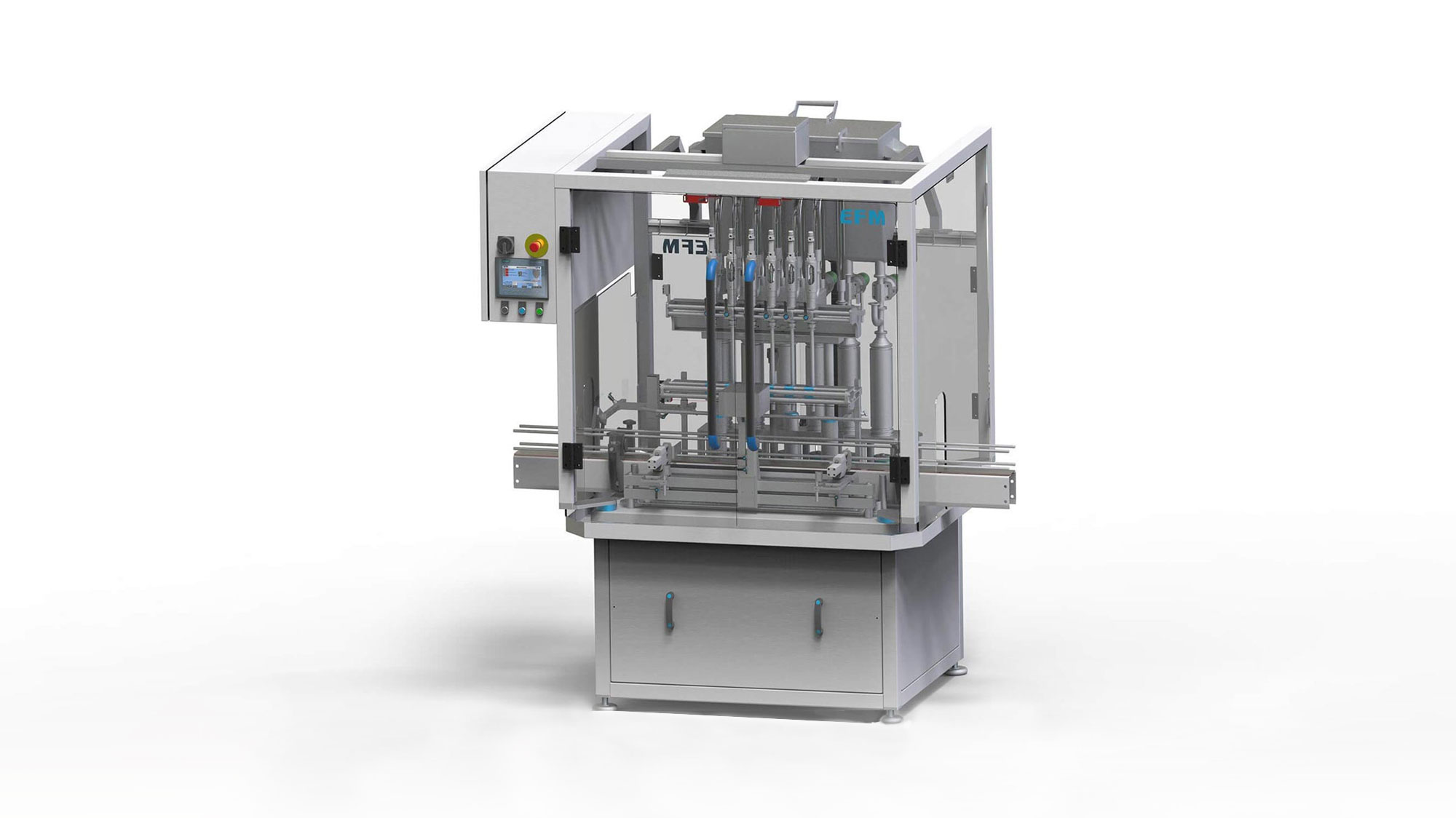

Are you in search of top-notch food packaging machinery to boost your operational efficiency? Since our successful establishment in 1997, EFM Machinery BV has emerged as a globally recognized expert in filling, closing, labeling, conveying, cartoning, and transporting bottles and jars across diverse industries. Leveraging our extensive experience, expertise, and innovative mindset, we consistently deliver tailored solutions to meet your unique requirements. Explore the value our food packaging machines can bring to your company.

Specialized food packaging machinery and cutting-edge technology

The majority of our products are crafted in-house, underscoring our commitment to quality. Our capability to integrate multiple solutions ensures seamless alignment with your needs. Our food machinery for processing and packaging food products streamlines and automates your workflow. Discover our past projects, showcasing successful implementations of our food machinery solutions for processing and packaging perishable food items.

About EFM Machinery BV for food packaging and processing

From our remarkable beginnings in 1997, EFM Machinery BV has flourished into a thriving global authority in food packaging machinery. We offer a comprehensive range of machines tailored for the food industry, including:

Drawing upon our experience, expertise, and innovative approach, we consistently deliver exceptional solutions for our clients. As a compact and flexible organization, we prioritize a practical and results-driven approach. Our ultimate goal is to enhance your business. That’s why we always prioritize a personalized approach, crafting solutions designed specifically to fulfill your company’s needs.

Get in touch with us for a tailor-made solution

Are you interested in acquiring our food packaging machinery to elevate your business? We manufacture the majority of our products in-house, exemplifying our commitment to quality and our ability to integrate diverse solutions seamlessly. Please don’t hesitate to reach out to us with any inquiries regarding our food processing and packaging machines.