Tailor made filling and sealing line for hobby paint

For the Dutch industry leader of a large portfolio of hobby paints founded in 1899, EFM Machinery developed a tailor-made, very quick and compact filling line to process small paint containers of 16ml and 50ml with a capacity of no less than 7,200 containers per hour.

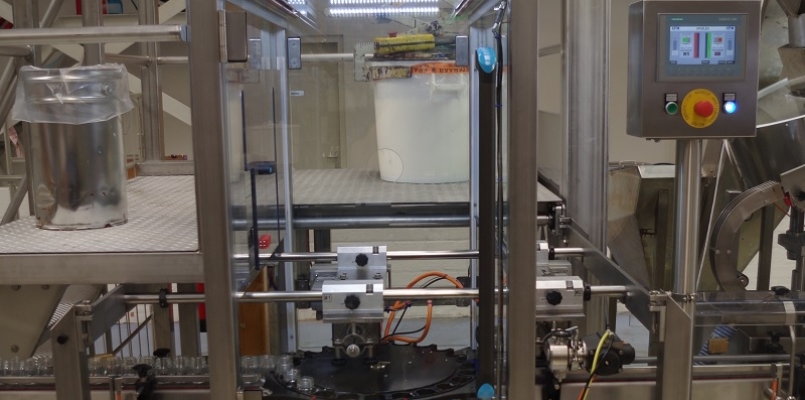

The filling machine is equipped with a double servo-controlled piston positioned above a servo-controlled position star. This position star ensures a highly accurate positioning under the filling heads and contributes to a very quick throughput of all filled containers without any shock effect. At the machine’s top side, the customer opted for a stainless steel plateau that supports an IBC or a bucket supplying the product to be filled. Both are equipped with a tilting mechanism.

Once the containers are filled, they are forwarded to a rotating six-headed sealing machine. All containers are sealed with the correct torque in a continuous process supported by our horizontal lid supply system (which became a default functionality for future machines). All further line inspections and controls have been equipped with a remote assist system.

The capacity of no less than 7,200 containers per hour depends on the volume per container and the product’s viscosity.