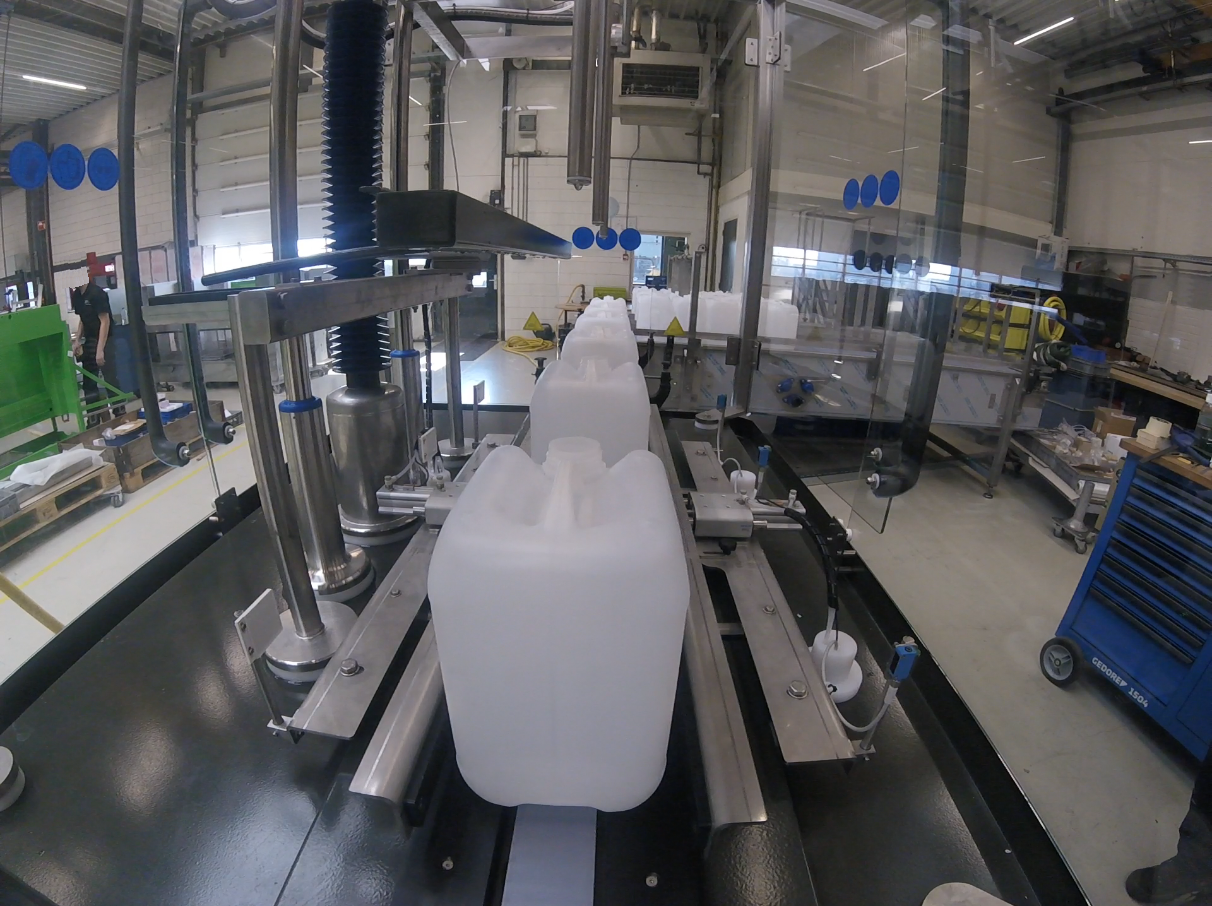

New jerry can filling line for chlorine based on net weight

10/04/2022

In cooperation with one of our metal processing partners in the Netherlands, we decided to install a joint filling line, with specific fillings and applications. In this case it was used for filling 20L jerrycans with chlorine and other specific products.

A special custom-made supply table ensures a constant supply of empty jerry cans to a branched conveyor.This special design of supply table and conveyor is required for operating with 3 individual load cells. The jerrycans are always positioned 100% at the correct angle, and must therefore be completely detached for correct weighing.

After filling, the filled jerrycans are moved to our standard bottle chain conveyor, to the ECO1 capping machine. This capping machine is fitted with a stopper system, to position the jerry cans correctly under the capping position, and was treated with a special coating, as was the filling machine.

A second – and third filling line of this type are now under construction, and will be described in a future website update.

The machine line consists of:

- Custom-made rectangular supply table with 3 rows

- Custom-made branched conveyor

- 3-head jerry can filling machine fitted with 3 individual weighing cells

- Jerry can heavy duty capping machine ECO1 treated with a special coating

- Discharge roller conveyor