Complete 2.1 ATEX filling and capping monoblock line for jerrycans

After implementing the first ATEX filling line for small-size packaging in 2019, a similar solution was now required for processing 2.5L to 30L jerrycans, also under ATEX conditions.

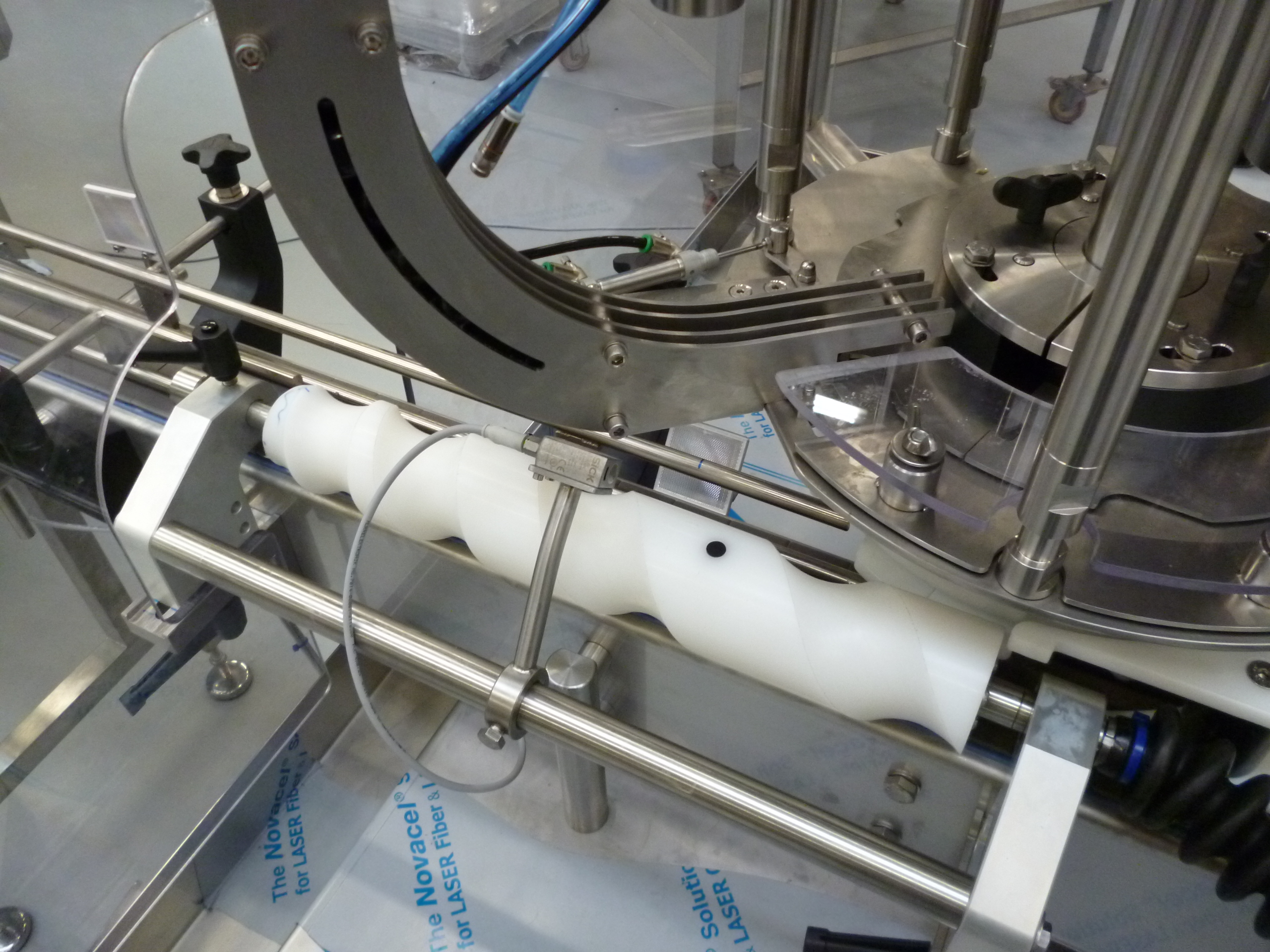

For this purpose, a fully automatic ATEX line was installed, comprised of an extended rectangular supply table mounted parallel to the filling and capping monoblock, due to the available production space.

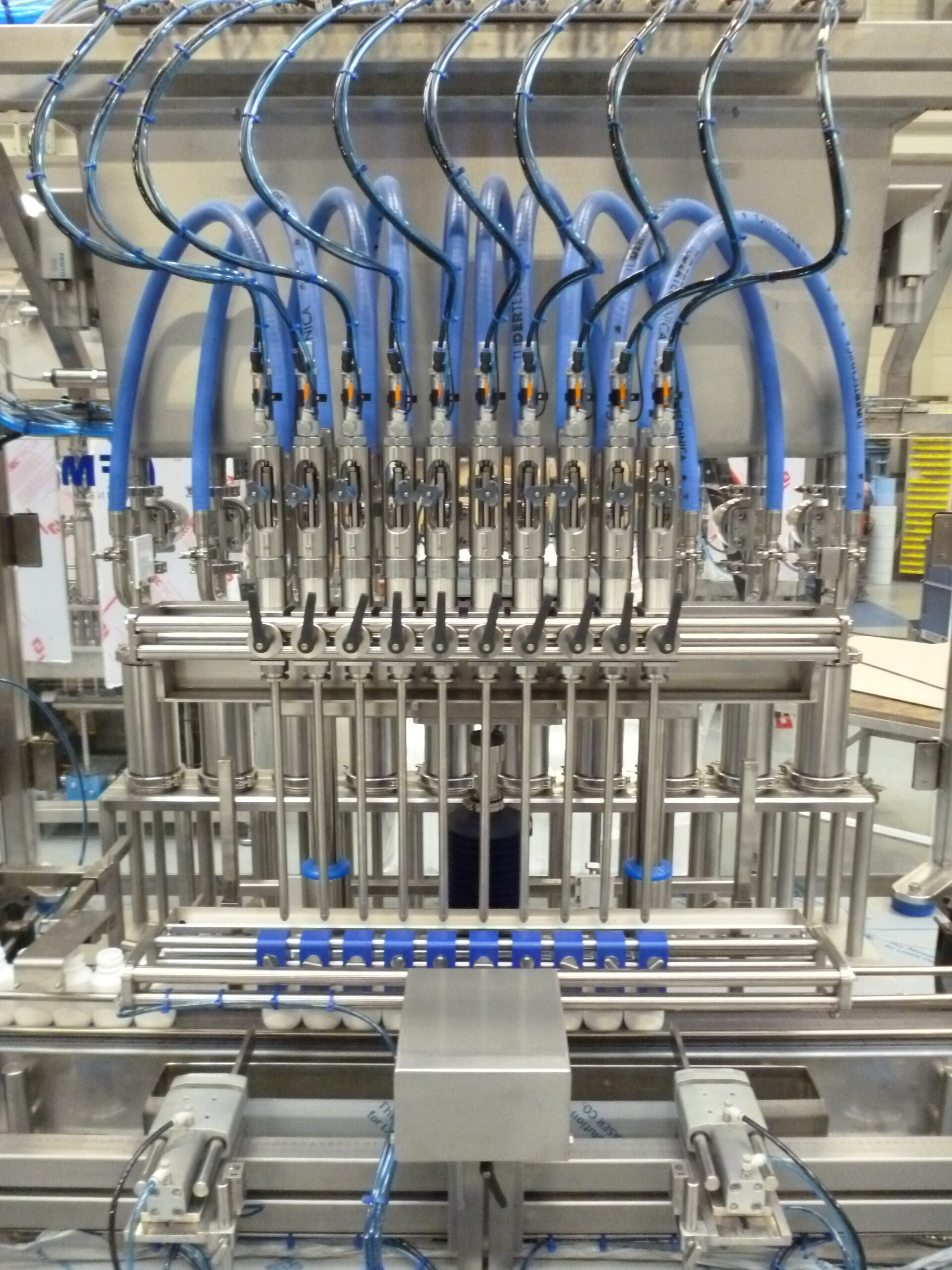

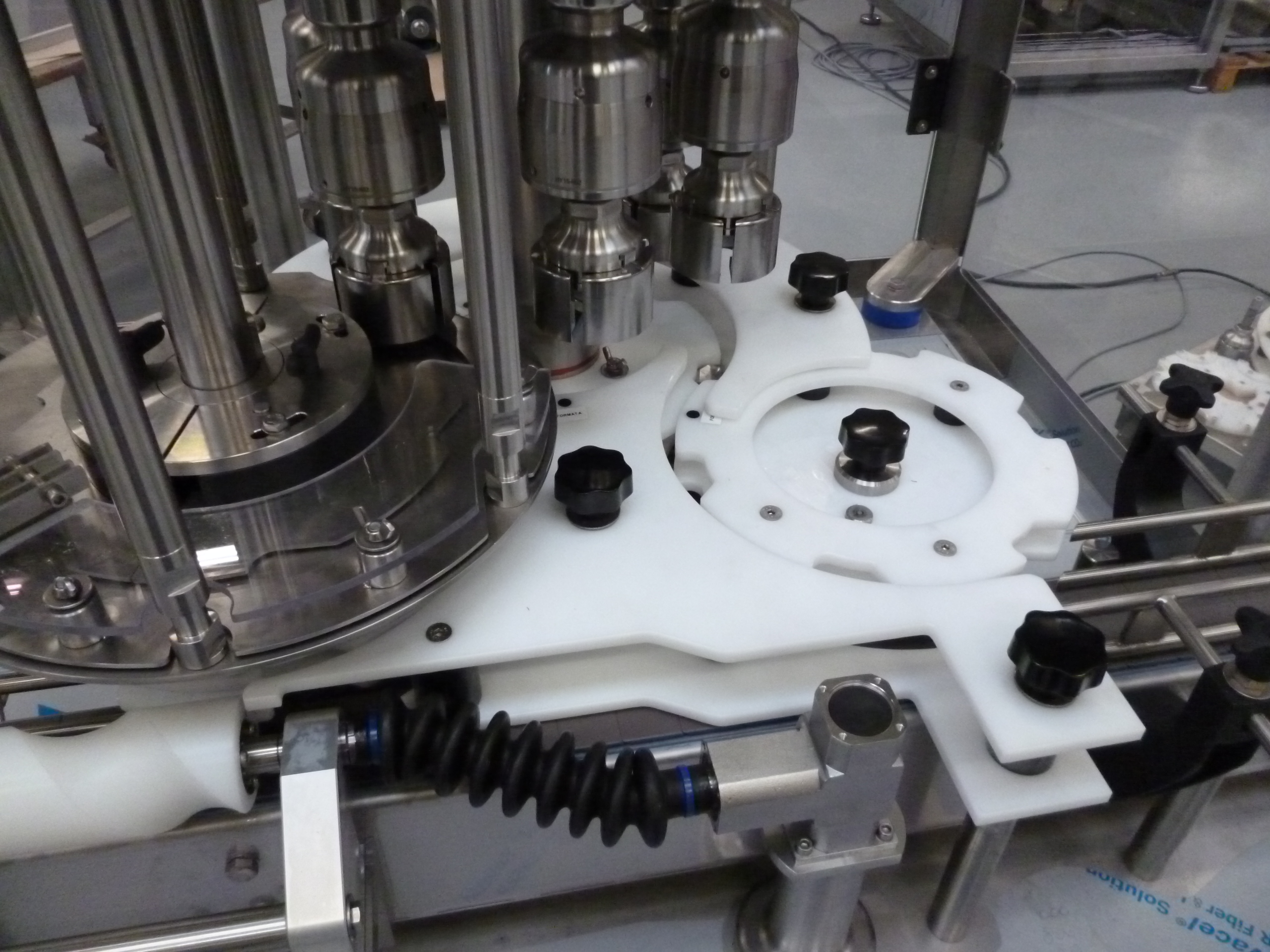

In order to be able to achieve the current stipulated capacity, a 2.1 ATEX monoblock was developed, equipped with 2 mass flow meters with an integrated grade 316 stainless steel 500L buffer tank. An ATEX twin screw pump provides the required supply from the existing external stainless steel buffer tanks. This is fully equipped with safety glass. The jerrycans are automatically fed using an extended rectangular supply table, and automatically filled and capped in the 2.1 monoblock system. The jerrycans are then labeled on both sides. The entire unit is linked to our remote assistance facility. The whole line has been designed in such a way that it can be expanded into a 4.1 monoblock during a later phase, making it easy to double the capacity.

Machine line consists of:

- Extended rectangular supply table

- 1 Atex monoblock with 2 mass flow meters and 1 heavy-duty capping machine

- ET3000 labeling machine

- All required conveyor belts