Upgrade of existing engine oil filling lines.

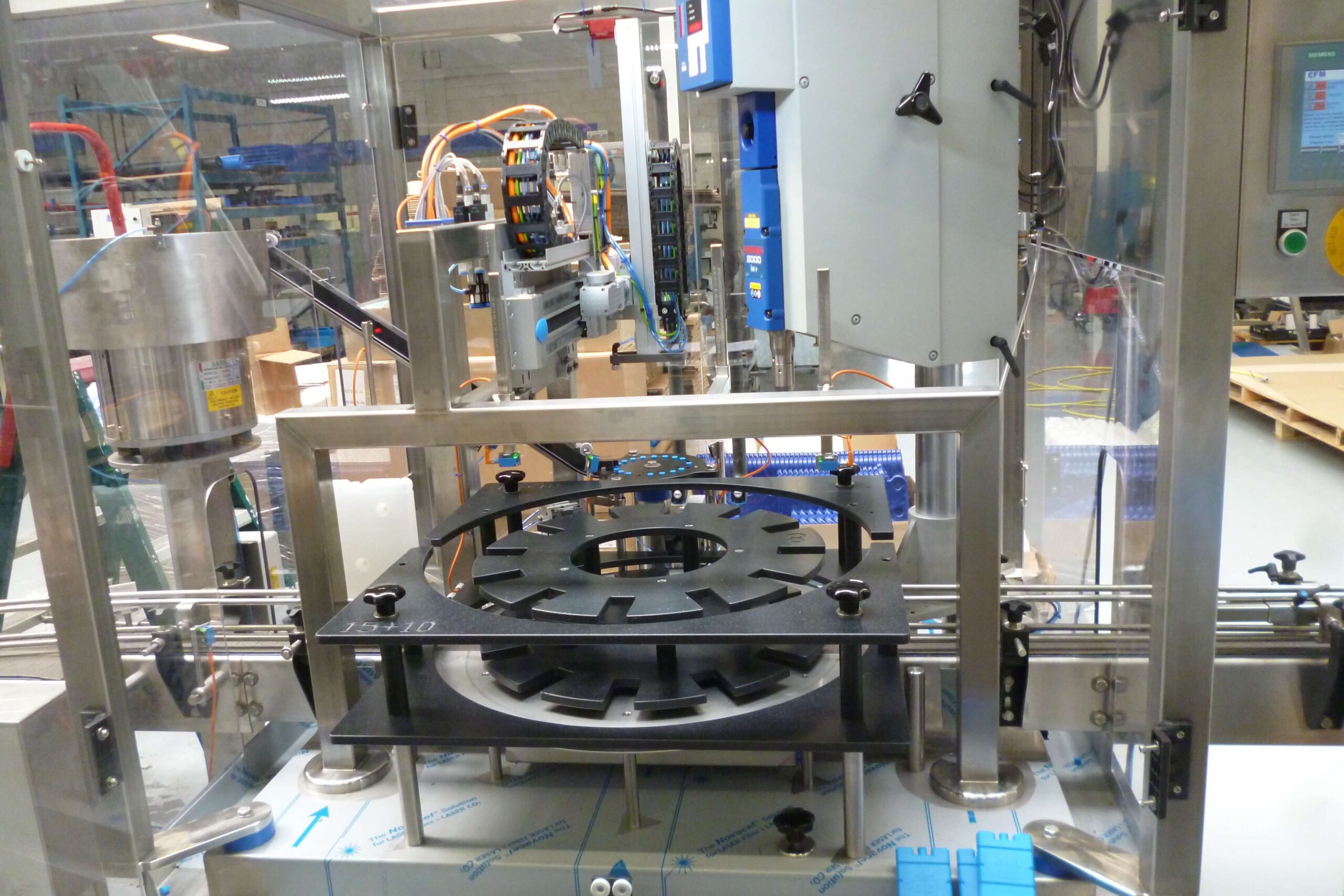

This Belgian company, which specialises in filling all types of engine oils and lubricants, has 3 complete filling lines. The two existing and outdated capping machines needed replacing, resulting in the acquisition of our flexible single capping machines. They decided on two ECO1-XL type capping machines.

Because the format needed to be changed several times a day, both capping machines were equipped with horizontal cap feed for efficient and safe accessibility. The XL, an extra large version, has the option to handle larger jerry cans as well as smaller 250ml cans. A detection and rejection system was fitted to the discharge side, with a stainless steel collection table in the event that a can passed through without a cap or with a cap that was not correctly sealed.

Both capping machines have been integrated into the existing filling lines, and can operate smoothly up to a capacity of 2200bph with all format parts for the cans and caps being interchangeable 1 to 1. Additionally, both capping machines have also been fitted with an extended feed and discharge conveyor to enable an efficient and smooth parallel transition from the filling machine to the existing labeling machine.

In the start-up phase, our remote assist also proved its usefulness once again by supporting operators, who at the time were inexperienced, in the shortest possible time and at no cost.

The extension to this filling line has been operational since the beginning of February 2018.

Meanwhile, a third ECO1 capping machine has been installed to process all small packs up to 1L. As a result, our standard version of the single capping machine proved to be more than sufficient and operates on the same basic principles as both ECO1 XL capping machines, making the setting and format changes for the line operators a breeze. The third capping machine was commissioned in September 2019.

Machine line consists of:

- 2 x ECO1-XL capping machine

- 1 x ECO1 standard capping machine