Steps in automation process for cold sauces

For many years the production of cold sauces in PET bottles was carried out using a semi-automatic piston filling unit and manually capped with a push-on cap.

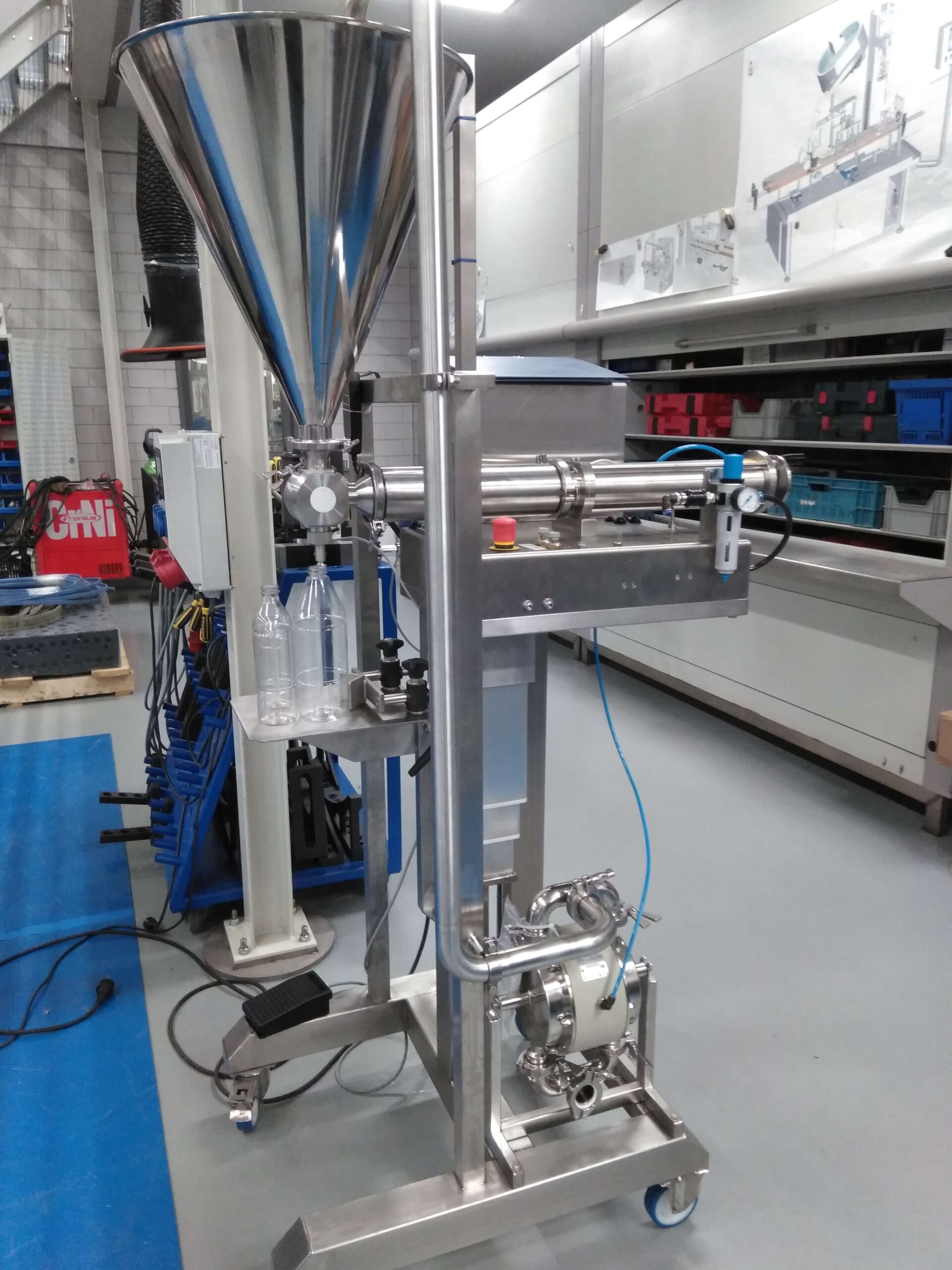

To improve production efficiency, our standard semi-automatic pneumatic piston filler was built on a robust and mobile stainless steel support, fitted with telescopic electric height control. A sanitary supply pump was installed at the base of the support, which was directly connected to the 200L standard trolleys. The pump is further controlled by the level control, mounted in the stainless steel funnel on top of the filling unit.

Our single ECO1 automatic capping machine will further ensure that the 3 PET bottle sizes are capped correctly using a push-on cap. The capping machine is fitted with a servo-controlled star so that the capacity can be increased to 2200bph in the future, when a fully automatic 4-header filling machine is installed in front of it. Our parallel transition further ensures a smooth transition to the existing labeling machine.

This complete filling unit with built-in pump was commissioned at the end of December 2019 and the automatic capping machine will be delivered in March 2020.

Machine line consists of:

- H/A V-Type filling machine with mobile support and electric height control and pump

- ECO1 capping machine