Standard filling line for juices

After installing several automatic fresh juice filling lines in the Netherlands and Belgium, our German customer then decided to install an automatic EFM filling line for processing fresh juices in square and round 3 PET bottle sizes.

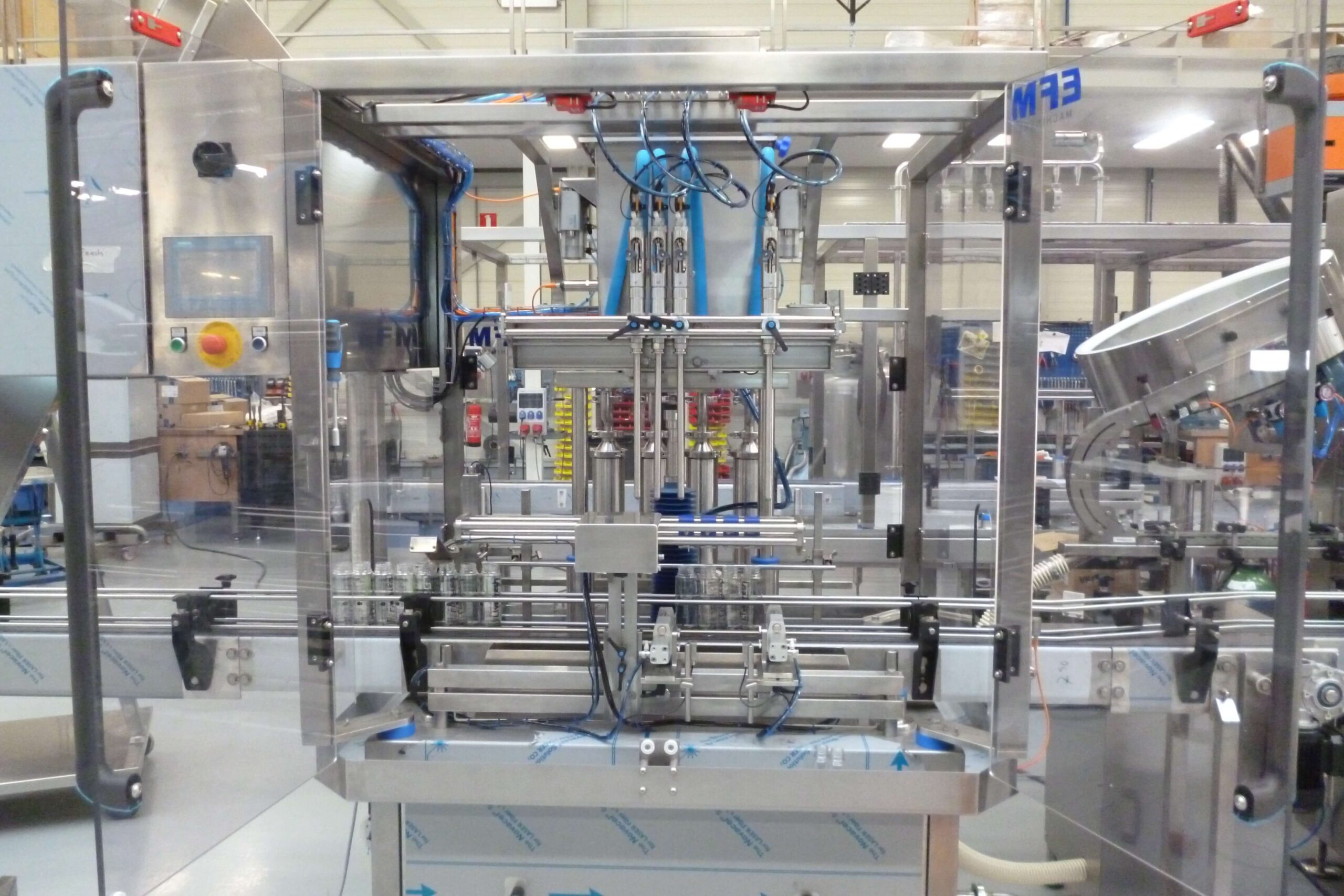

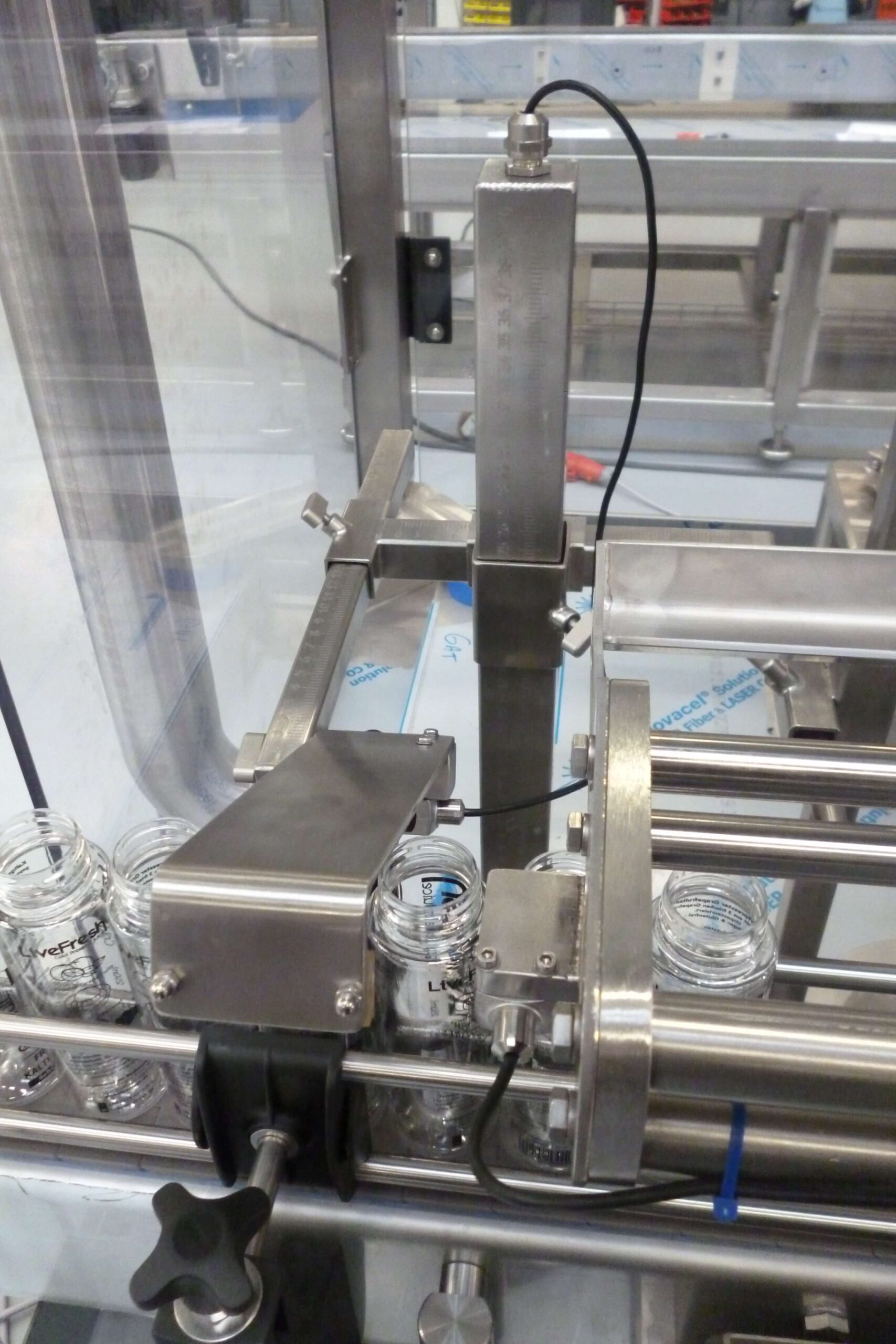

This line consists of a standard PS4 servo-controlled filling machine, fitted with all standard optional solutions regarding bottle presence control, as well as all elements to ensure a smooth and complete cleaning procedure. An existing pump ensures a correct product supply, and is connected to our level control, which is installed in the stainless steel product tank.

Our single ECO1 capping machine caps all filled bottles with 2 types of screw caps, operating at a capacity of 2000bph on 60ml bottles, and also 250ml and 750ml bottles. Subsequently the bottles are collected in separate bins for further HPP (High Pressure Processing) treatment.

After this specific product treatment, the bottles are manually placed on our rectangular flat deck table which transports the bottles to the double-sided labeling machine. The bottles are then centred and spaced, labels are attached on the left and right side, after which they are collected on our round buffer table where they are then manually packed in specific wraparound cardboard packaging.

This filling line has been operational since March 2019.

As a result of this huge success, it has now been decided to install a high-capacity line specifically for the 60ml shots, which can also be adapted to process the 250ml bottles. This filling line will have a capacity of 6000bph and will consist of an automatic unscrambler, our 10-header servo-controlled piston filler, our 6-header capping machine and a servo-controlled rotating labeling machine. Due to innovative developments, the labeled bottles can now also be processed using the HPP treatment. A separate packaging line will provide automatic packaging in American folding boxes. This filling line and packaging machine will be commissioned in August 2020 and is still ongoing.

To meet the initial increased production requirements, we’ll first provide a temporary filling line for our customer to use from the beginning of February 2020 until delivery of the new high-capacity line.

Machine line consists of:

- Rectangular flat deck table

- PS4 filling machine

- ECO1 standard capping machine

- ET3000 labeling machine

- Round loading table