Special Monoblock 4.2.2. combination for pharmaceutical company

This Dutch pharmaceutical company was looking for a highly flexible yet compact solution for filling and capping a wide range of specific applications. The requirement was that the system could handle square plastic bottles, in addition to glass bottles with special twist-off caps and shrink caps. This included putting rubber inserts and/or twist-off lids on glass jars.

A quick conversion time between these very different applications was a very important aspect, to ensure that the necessary “down time” could be kept to an absolute minimum.

A special 4.2.2. monoblock was developed for this purpose, consisting of several stations, each of which was fully configured for each application. Because of the nature of the products, four peristaltic filling units were fitted, using individual filling nozzles with positive shut-off.

After filling, four specific and targeted capping systems were fitted for each application, so that no conversion is required between these specific caps and seals. Now it is a simple choice of which system to use per production unit. These consist of vibrating bowls as well as air hoppers, depending on the applications, and are fitted with pick & place units or discharge systems.

Because of certain standards in print & apply labeling machines, an external print & apply system was integrated, together with the required controls and sensors.

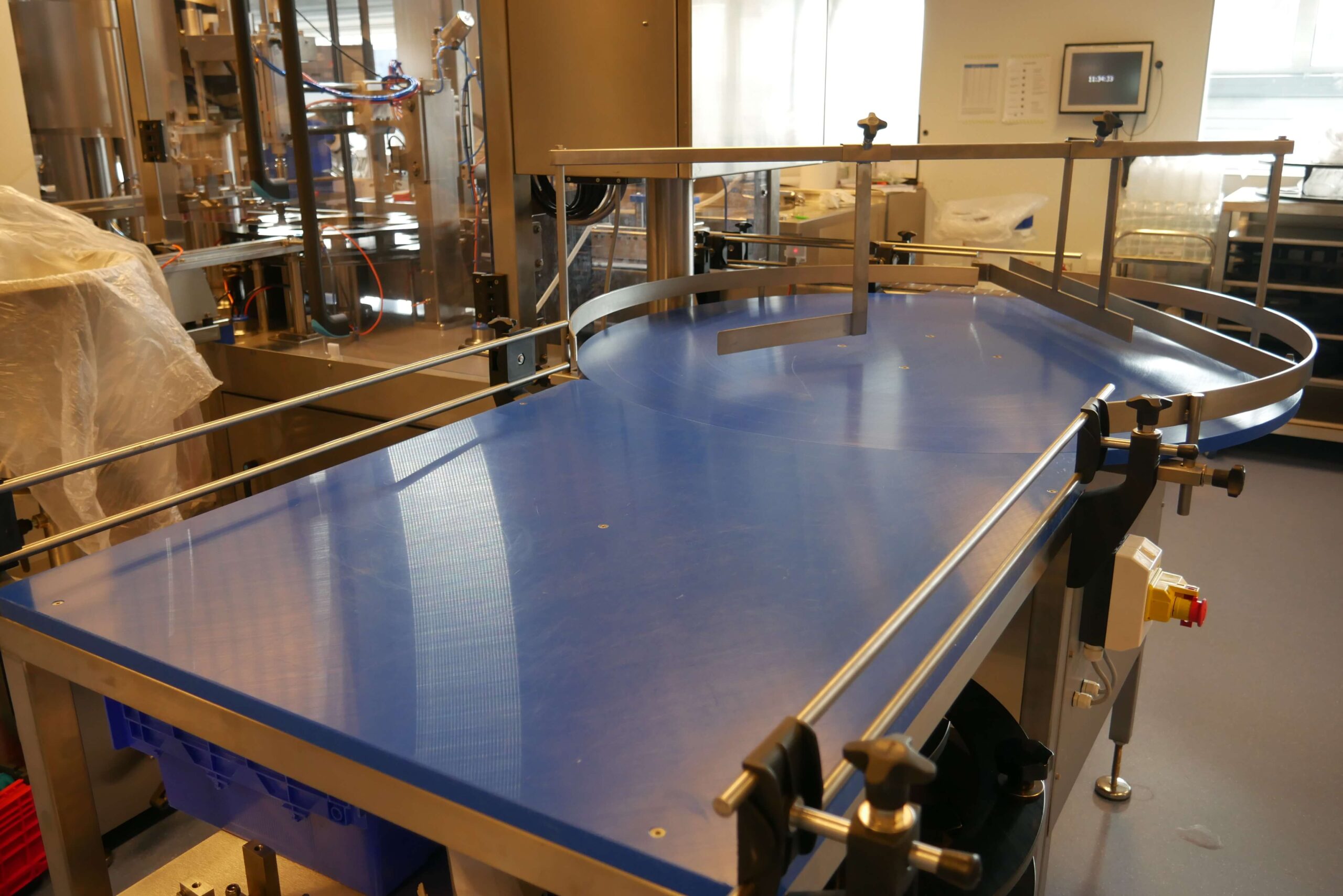

A round supply table with stainless steel feeder tray ensures a constant supply of empty packaging and the round buffer table collects the finished packaging for further manual packaging, up to a production capacity of 1800bph. The total length of this filling line is less than 6500mm.

This filling line has been operational since March 2018.

Machine line consists of:

- Round supply table

- Combination machine

- Labeling machine

- Round buffer table