Monoblock compact filling line for small hotel jars

This existing Belgian customer, who processes high-quality honey products, wanted to expand further, specifically to process glass hotel jars (30g and 50g) that had originally been filled on a previous flexible filling line. The oval glass bottles (500ml) filled with propolis syrup and capped with screw caps are also processed on this line.

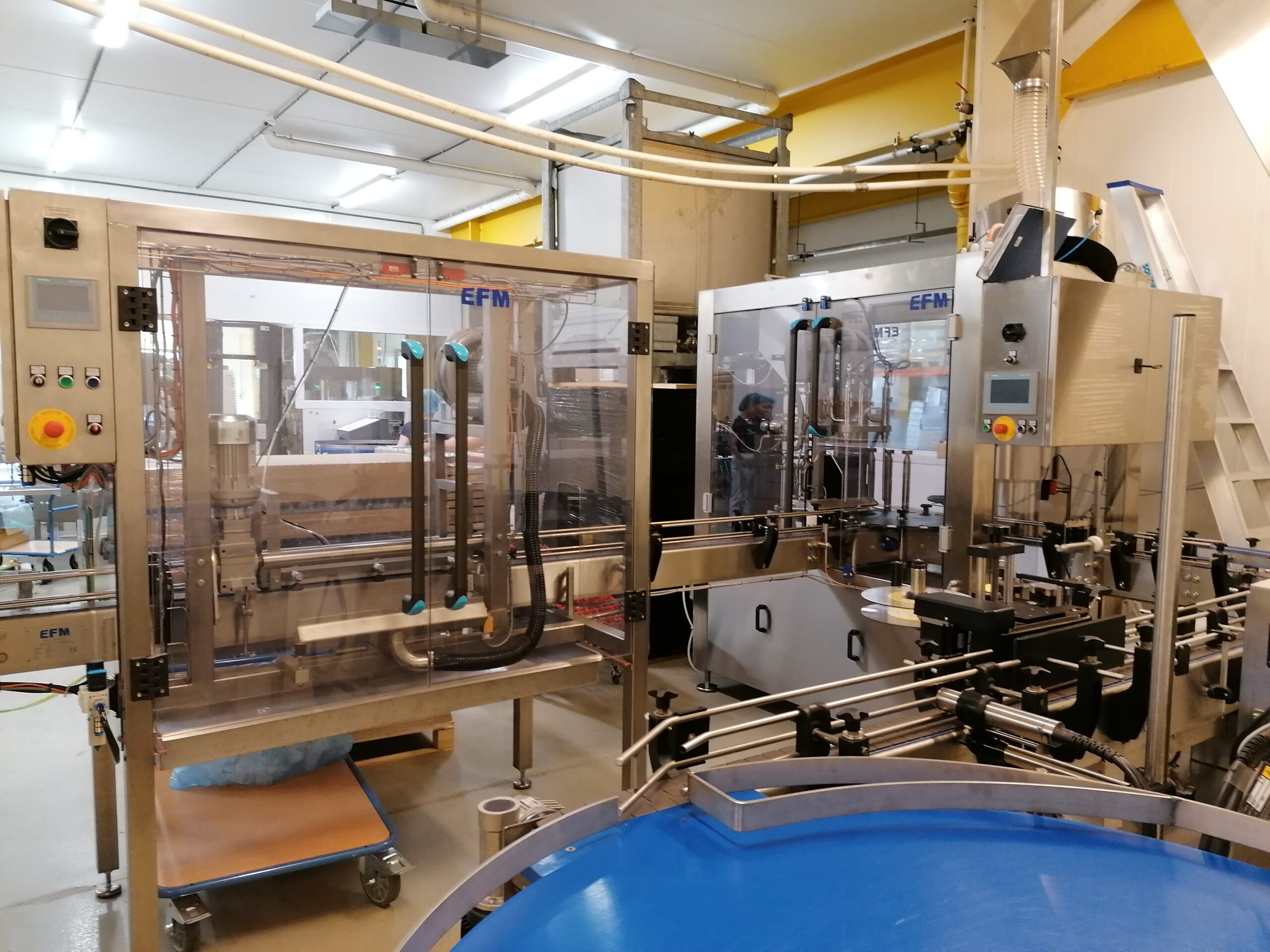

The empty glass jars are placed on the round supply table and are first blown out by our linear rinser (size-independent), after which they are fed into the 3.1 filling and capping monoblock system. The twist-off lids are heated slightly in the feed chute so that the coating bonds better after capping.

After being capped, the jars are transported away and given a wraparound label and coding, and are then collected on the round loading table. One operator controls both the infeed and outfeed side, thanks to the buffers provided, and operates this line at its maximum capacity of 1700bph.

Machine line consists of:

- Round supply table

- 1 Compact filling and capping monoblock

- Inline air rinser

- Labeling machine for wraparound labeling

- Loading table