Flexible line commissioned by a logistics giant in the port of Antwerp.

After a preliminary research taking almost 3 years involving several project managers, this logistics giant in the port of Antwerp with operations and depots worldwide, decided to invest in a complete and flexible filling line to fill mainly motor oil products, as well as detergents, cleaning products, etc.

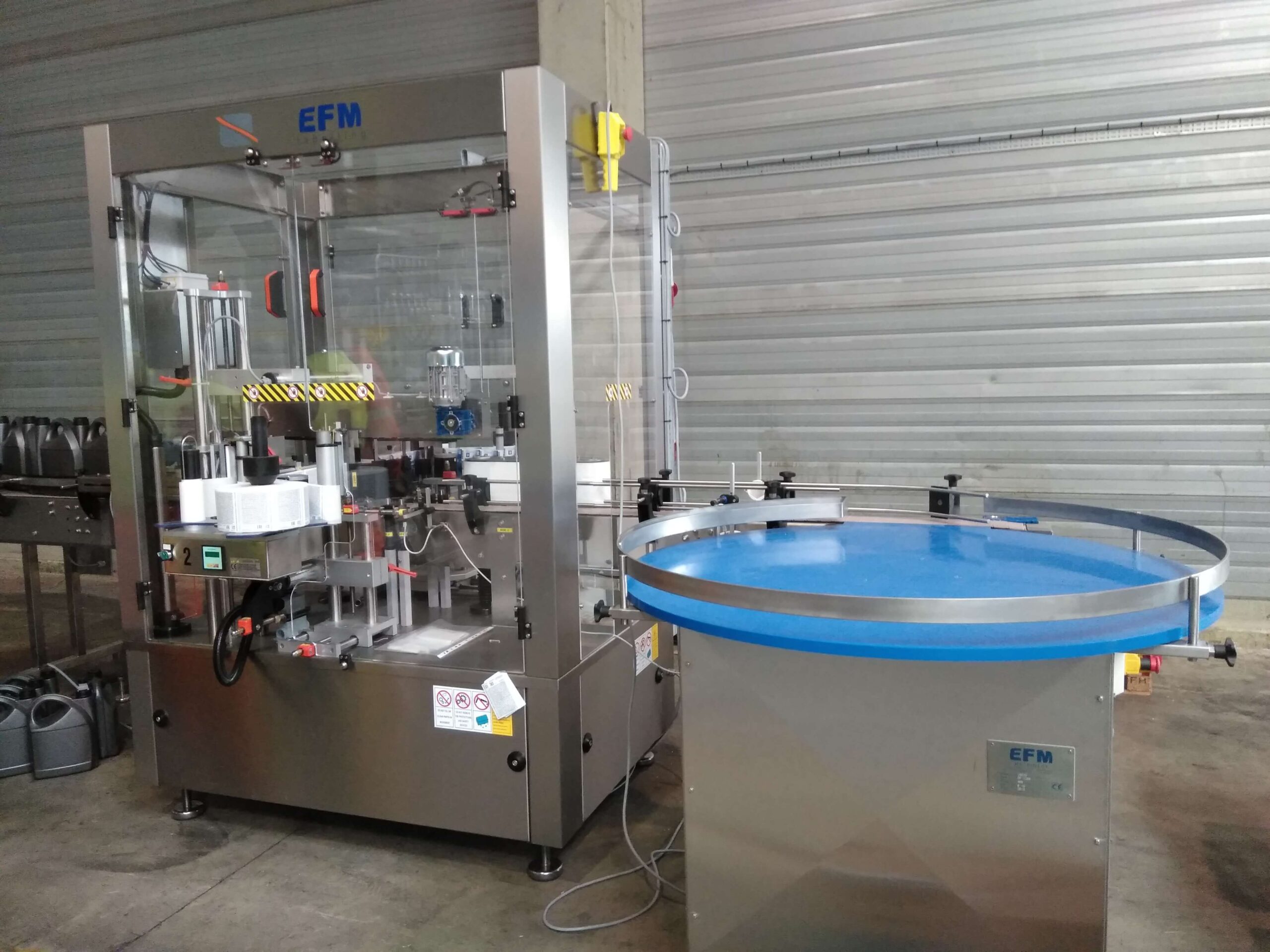

This filling line consists of a rectangular flat deck table with inliner to also be able to process round packaging, and a 6-header flow meter filling machine that can be extended to an 8-header in a second phase. This machine is also fitted with a 1.6 collector for thorough pressure cleaning and, additionally, with short steam injection in a closed circuit. A single servo-controlled ECO1 XL capping machine with horizontal cap feed ensures all caps are sealed correctly. An automatic induction sealer seals the cans. A full-option linear labeling machine ensures round cans are labeled correctly; double-sided labelling and oval packaging are perfectly centred. A loading table buffers the finished packages.

This complete line can reach a capacity of up to 2200bph based on 1L packages, and is operated by 2 line operators who ensure that the empty packages are supplied and the finished packages are packed and palletised.

This filling line has been operational since the beginning of July 2018.

Machine line consists of:

- Rectangular extended supply table

- 6-header flow meter filling machine

- ECO1-XL capping machine

- ET3000 labeling machine

- Round buffer table