Automatic filling line for cold sauces

This standard filling line allows for the correct processing of cold sauces (between 260ml and 1000ml) in 3 different squeeze bottles which are capped by two different flip-open twist-off lids, with an average capacity of 2000 bottles per hour. The machine’s standard equipment also allows for an efficient and very accessible cleaning procedure by means of, among other things, a piston from a cylinder position, filling nozzles in automatic rinsing position, spray balls in the product tank, as well as the lift system to raise the tank using the touch screen, which means that it never needs to be disassembled. The individual V-centring secures a correct positioning of the filling spouts beneath the filling nozzles before the filling cycle starts. The bottle counting system ensures that the filling cycle cannot operate if no bottles are present.

A pipe for the metal detection system was built into the unit and positioned between the supply pump and the stainless steel product tank.

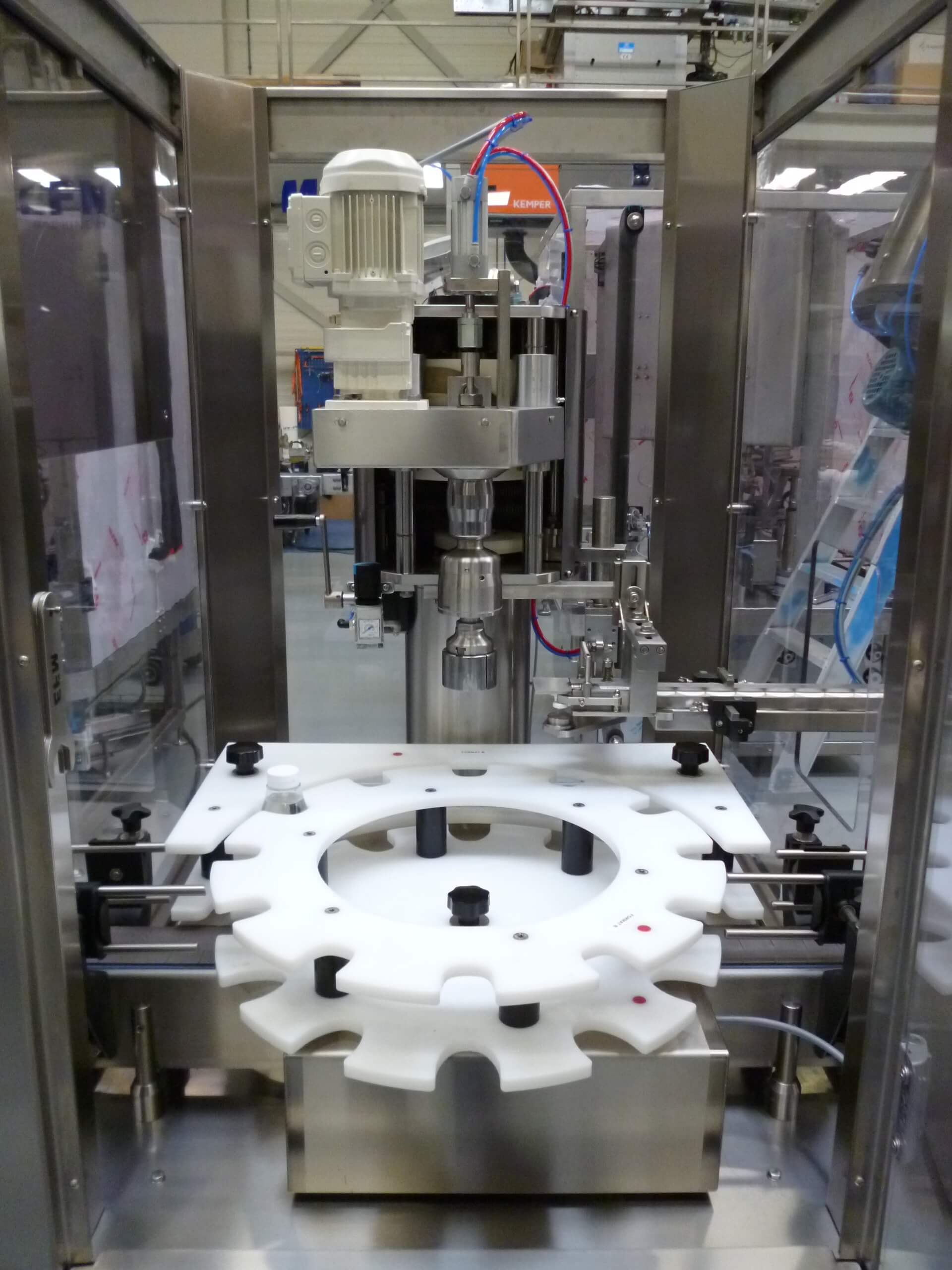

Our single ECO1 capping machine ensures the various flip-open twist-off lids are aligned correctly. The format change is easy due to the fact that the cap sorter is mounted next to the capping machine at working height.

An existing labeling machine was integrated into the entire line setup at the same time, and the finished bottles are collected using our round buffer table.

This line was commissioned in November 2019.

Machine line consists of:

- PS6 filling machine

- ECO1 capping machine