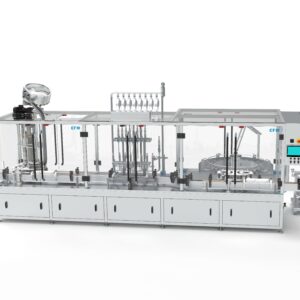

Tube filling- and capping machine

Elevate your business operations with a top-notch tube capping machine. At our in-house facility, we meticulously develop and manufacture these machines to guarantee superior quality and unmatched durability. As a leading manufacturer in the industry, EFM Machinery BV specializes in tailor-made solutions for international clients across diverse sectors. Explore our wide range of products to enhance the efficiency of your production process and boost your overall business performance. Find the ideal tube capping machine that perfectly aligns with your company’s requirements.

Discover the ideal tube capping machine for your business

Our tube capping machines are meticulously crafted from stainless steel, ensuring exceptional durability and unmatched quality. Designed to automatically secure caps onto various packaging materials, this type of capping machine is perfectly suited for aluminum and plastic tubes. It accommodates diameters ranging from 10mm to 60mm and lengths varying from 50mm to 250mm, making it an excellent choice for food products, pharmaceuticals, cosmetics, and chemical applications. Engage with us to discuss your specific needs, and we’ll provide expert advice on the available editions, tailored to your volume, size, and tube material requirements. Apart from a tube capping machine, some other possible capping solutions are:

Place an order for the perfect machinery for your company

Procure a tube capping machine that precisely caters to your business requirements. As your trusted partner in enhancing your operations, we offer a comprehensive selection of food packaging machinery, designed to optimize your business performance across multiple industries. If you have any inquiries regarding different machine designs or their suitability for specific sectors, reach out to us. We’ll promptly address all your queries!

Standard features

- Stainless steel construction

- Able to process aluminium and plastic tubes [of: processing aluminium and plastic tubes]

- Integrated buffer with automatic feed

- Mechanical piston filling system for liquid and thick viscous products

- Very open and accessible machines

- Very quick and easy format change and application

- Pre-heating station for plastic tubes

- Folding station for aluminium tubes

- Coding in seal

- Siemens PLC with touch screen

Various designs available by capacity, depending on volumes, size and tube material.

- MTR40/50/70 : 600to4800bph

- MTL100 : 6000bph

- MTL100/2 : 12000bph

- MTL200 : 12000bph

- MTL200/2 : 24000bph

- MTL400 : 24000bph