Complete filling line for peanut butter bird feed commissioned at English production company

Via our Dutch client, an extensive project arose near the English city of Birmingham for the production of peanut butter bird feed. Different sizes of round jars needed to be filled, some of which were sealed using insert lids, and other glass jars with twist-off lids. This arrangement was very specific and had multiple applications.

After filling, some products are transported to an external cooling unit installed in a sea container and which is positioned directly next to the production area, and then packed immediately on a tray seal dispenser. After filling, the other jars are sealed with a screw lid and then given a wraparound label and collected on the loading table.

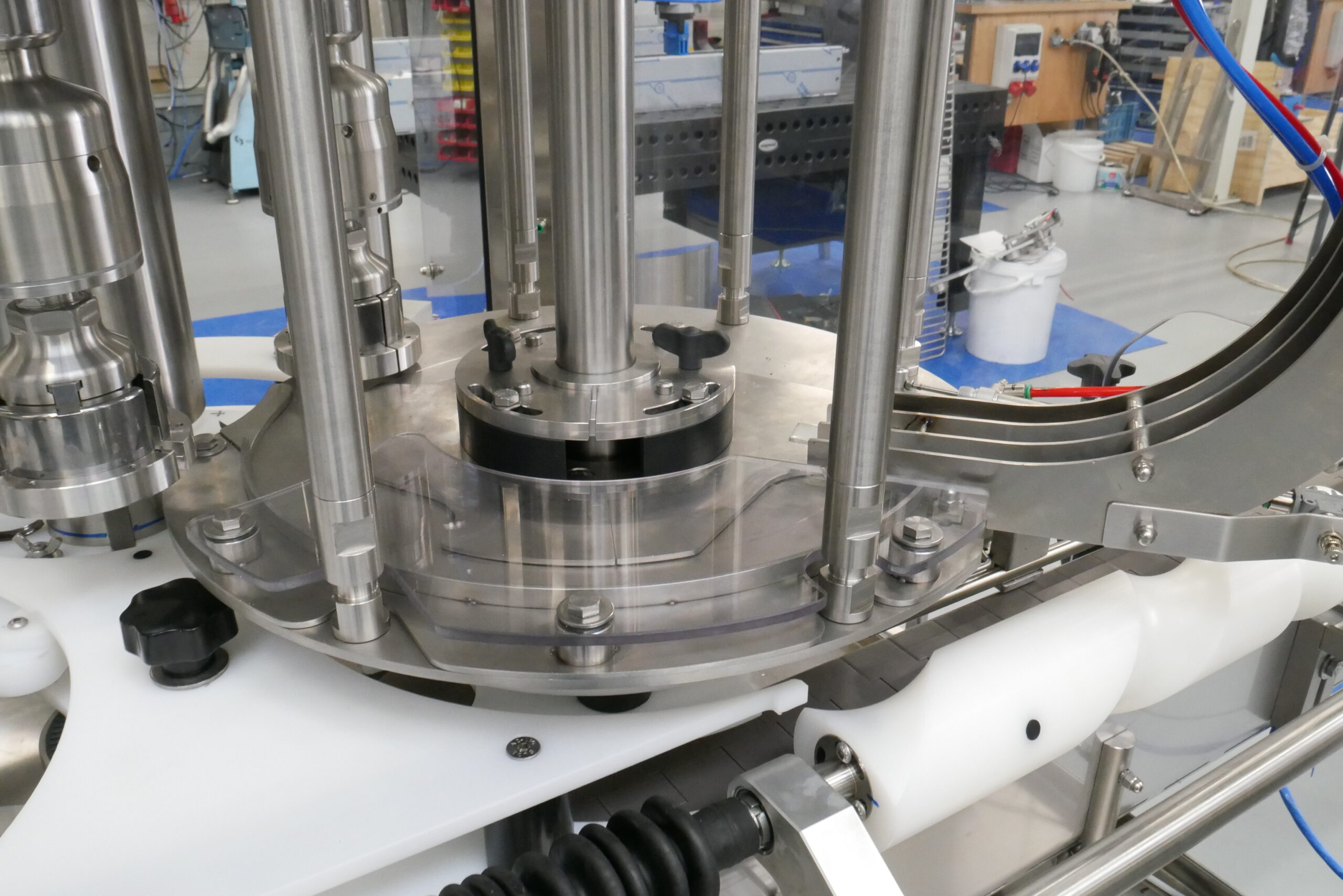

For this operation, a rectangular supply table was supplied which feeds the empty packs to the 8-head servo-controlled PS8 piston filling machine, where these products are filled at a temperature of 45°C. The glass jars are fed directly to the 4-head RS4 capping machine and then processed by the wraparound labeling machine. After this, the finished products are collected at the round loading table.

Machine line consists of:

- Rectangular flat deck table with inliner

- Integration of destacking system

- 8-head servo-controlled piston filling machine

- 4-head capping machine

- Labeling machine for wraparound labeling

- Import and export conveyors, as well as interconnecting conveyors

- Round collection table

- Cooling system installed in sea container