Sauce filling line

This renowned Belgian sauce producer offers a large assortment of high-end sauces and dressings in buckets and large pots.

The client now also wanted to start a production line in order to offer smaller containers. This is why they were looking for a highly flexible and compact production system, able to quickly vary between sizes to fill, seal, induction-seal and label squeeze bottles.

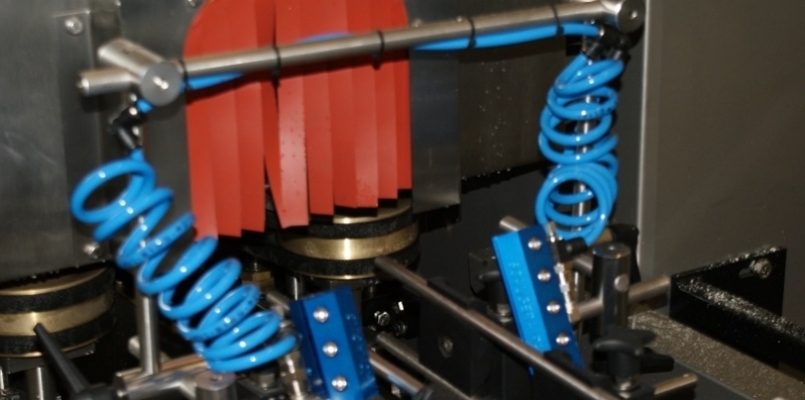

Based on this need, the client invested in a custom made EFM filling line, consisting of a rotating flat deck table, a bottling and sealing Rotary Monoblock system, a Mero Induction Seal System and a Newtec Full Option labeling machine. The end result provides for a processing capacity of 1,500 bottles per hour.

Additionally, the client was also requested delivery of various sizes of glass jars. The filling line was thus adjusted to accommodate for this need and expanded with an automated twist-off sealing machine.