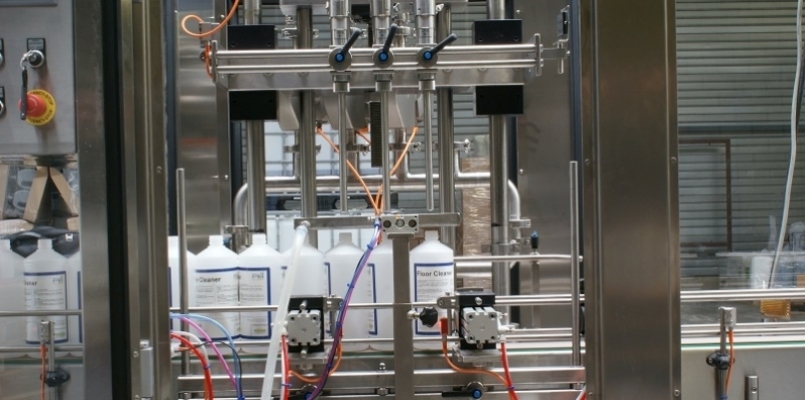

Monoblock system

This project required processing 15 different types of bottles and eight different types of caps. That’s why we opted to offer a Monoblock configuration.

A three-headed Mass-flow meter filling unit (extendable to four heads) automatically fills the bottles. In the second segment, measuring 1,700mm, the operators manually placed the caps on the bottles. The cap sealer then ensured that all types of caps were automatically sealed. After several months of successful production, the basic sealing machine was further expanded to fully automate processing of the most important containers. The existing ‘trigger’ sealer and the labeling system where then connected to it.

This project once again proves the added value of a ‘growth concept’, in which the client is always in full control about the decisions and requirements for further automation.