Extra 1-head capping machine integrated into existing tube line

This existing client, who already has several EFM filling lines for processing alcoholic beverages, needed to add a new application to the existing tube line to cap small plastic tubes using a ROPP cap instead of the original push-on caps.

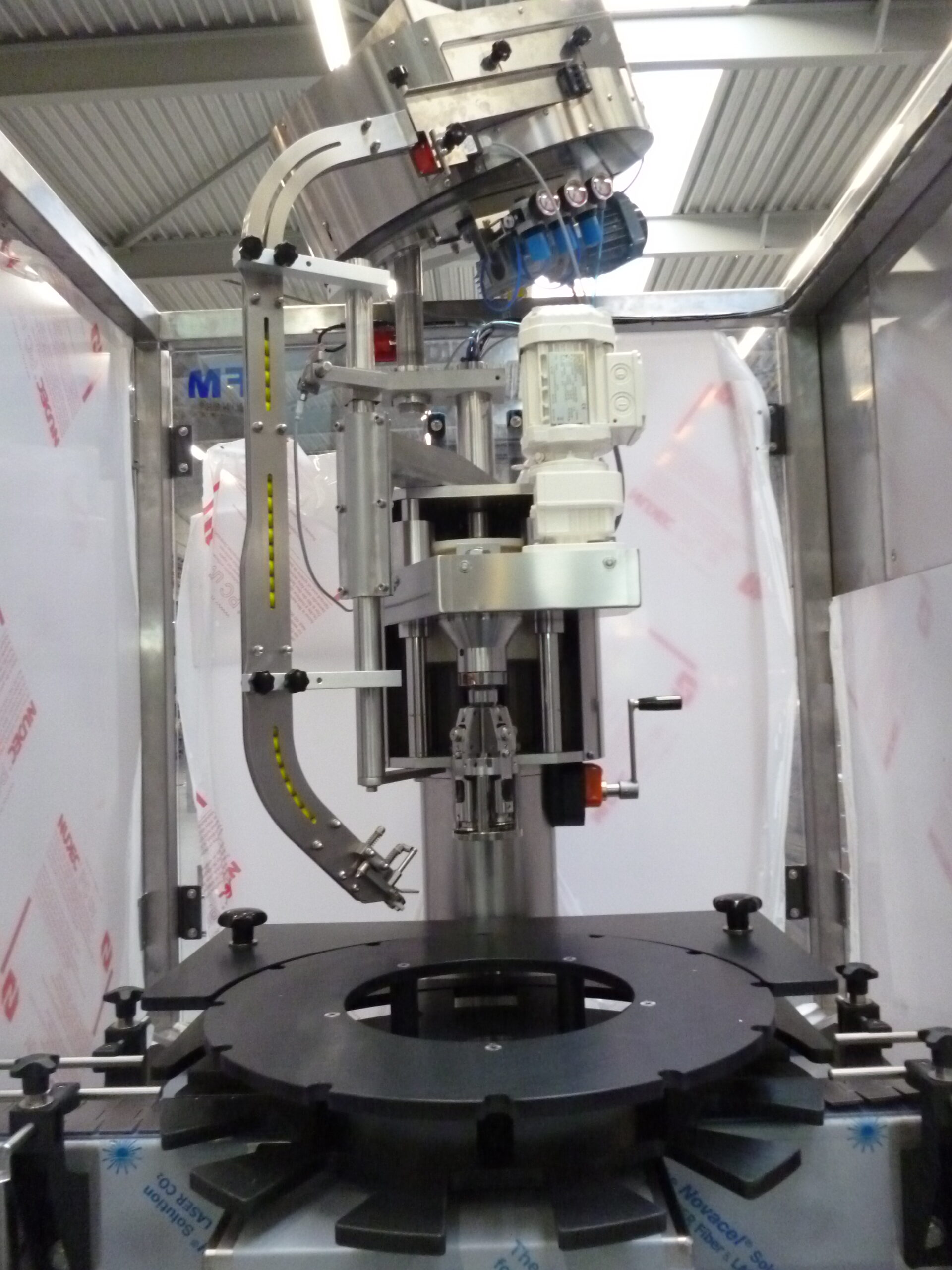

To do this, the existing track carousel was adapted and an automatic ECO1 capping machine was installed and equipped with the small ROPP cap discharge system, and a star wheel of the same size as the existing one. The new pucks are servo driven so that a capacity of up to 2500bph can be achieved without shocks, and any spillage is avoided.

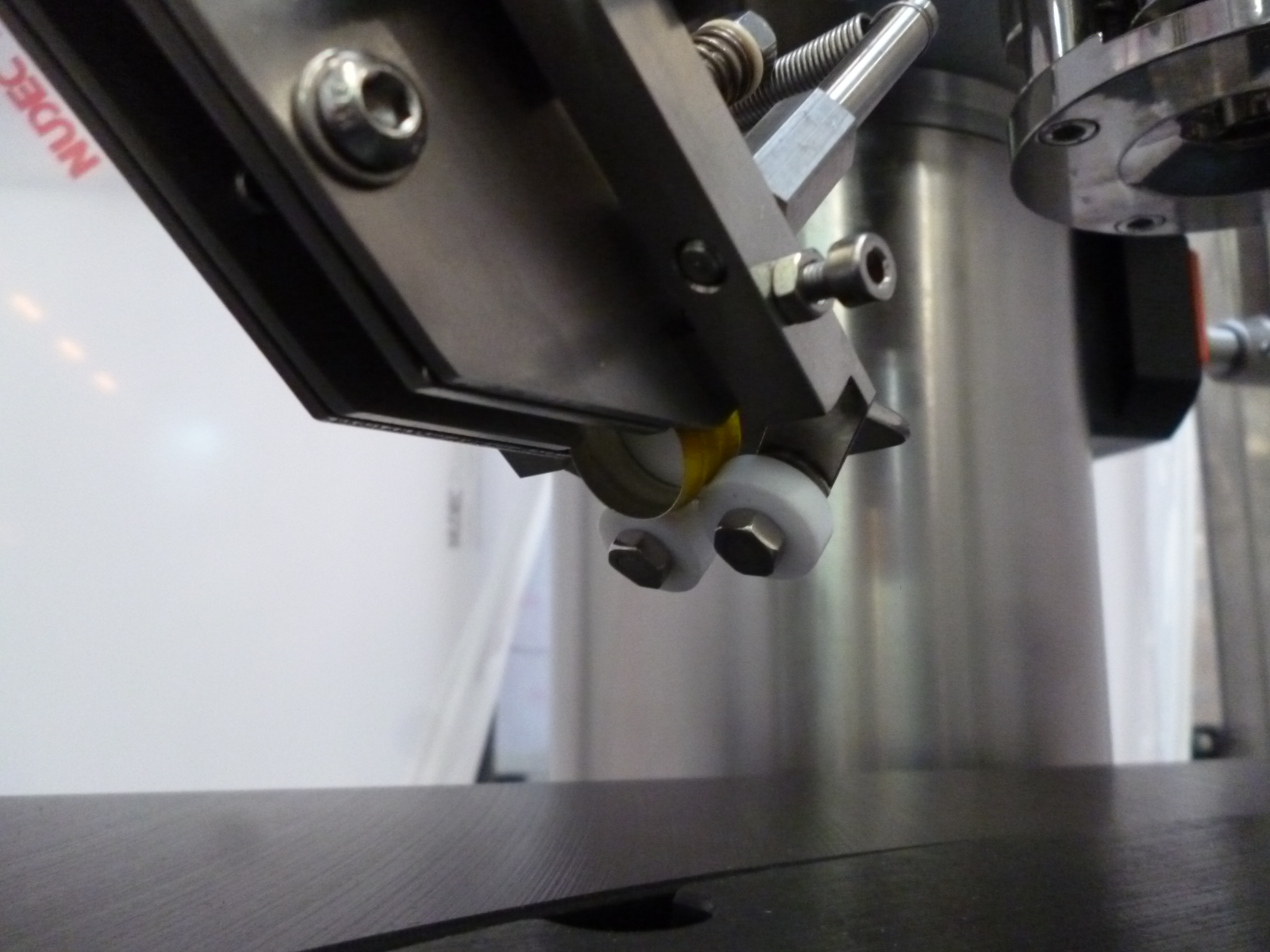

An additional labeling head needed to be installed for this new application, and it was fitted with a separate roll-over station, whereas the previous applications had been fitted with a shrink sleeve.

Machine line consists of:

- 1-head ECO1 capping machine

- Label head with separate roll-over station.