Complete filling line for German manufacturer of preserves & jams

20/10/2021

After a period of research into the best possible and most flexible solution, we jointly opted for a flexible filling line, taking into consideration that a very fast changeover to other products would be required.

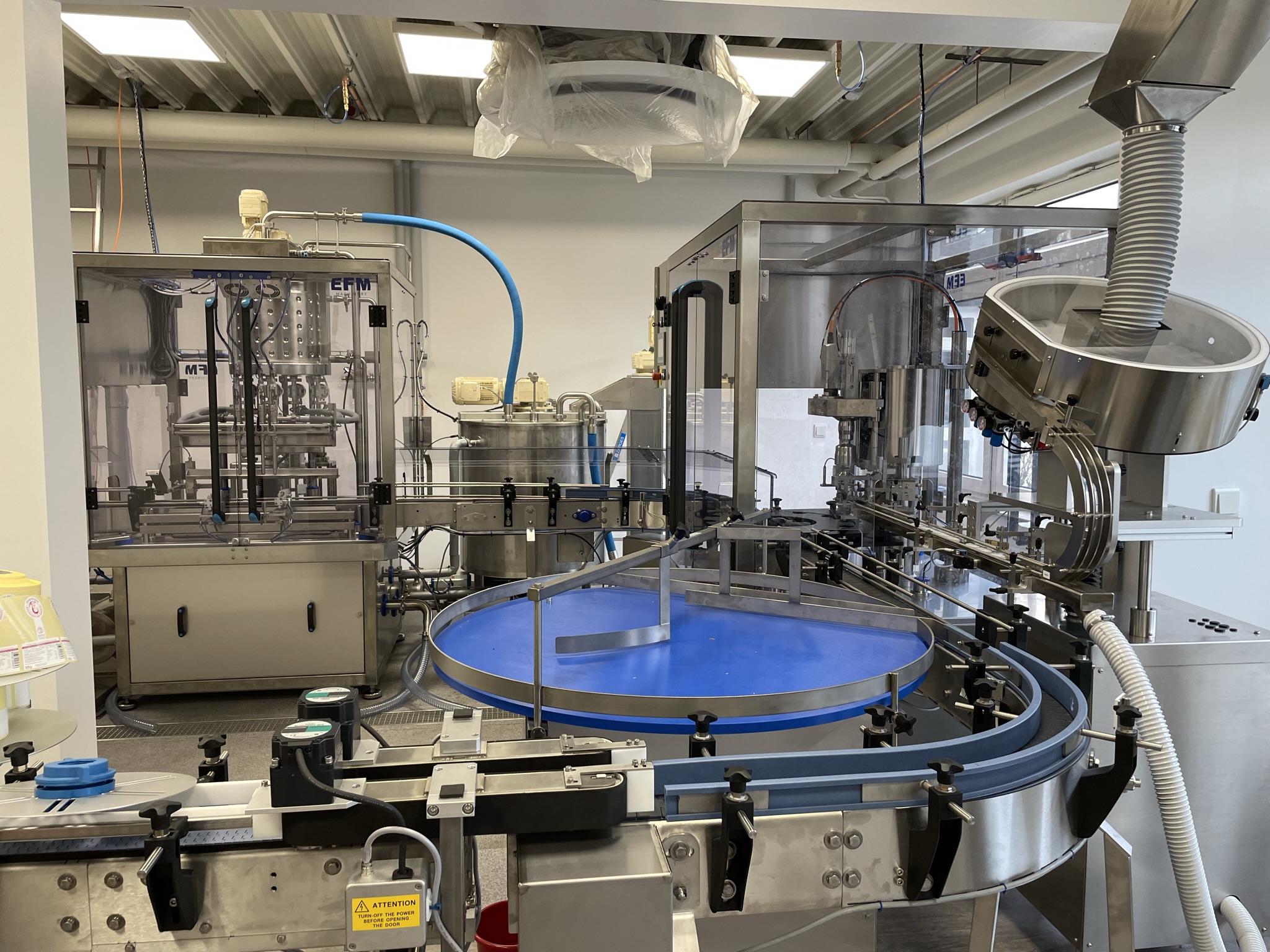

The round glass jars are placed on the supply table and fed into our standard inline air rinser, and transported to the PS4 filling machine. The buffer tank is fitted with a vertical agitator. All possible provisions were made to ensure fast and easy cleaning of the entire filling plant with very limited operator intervention.

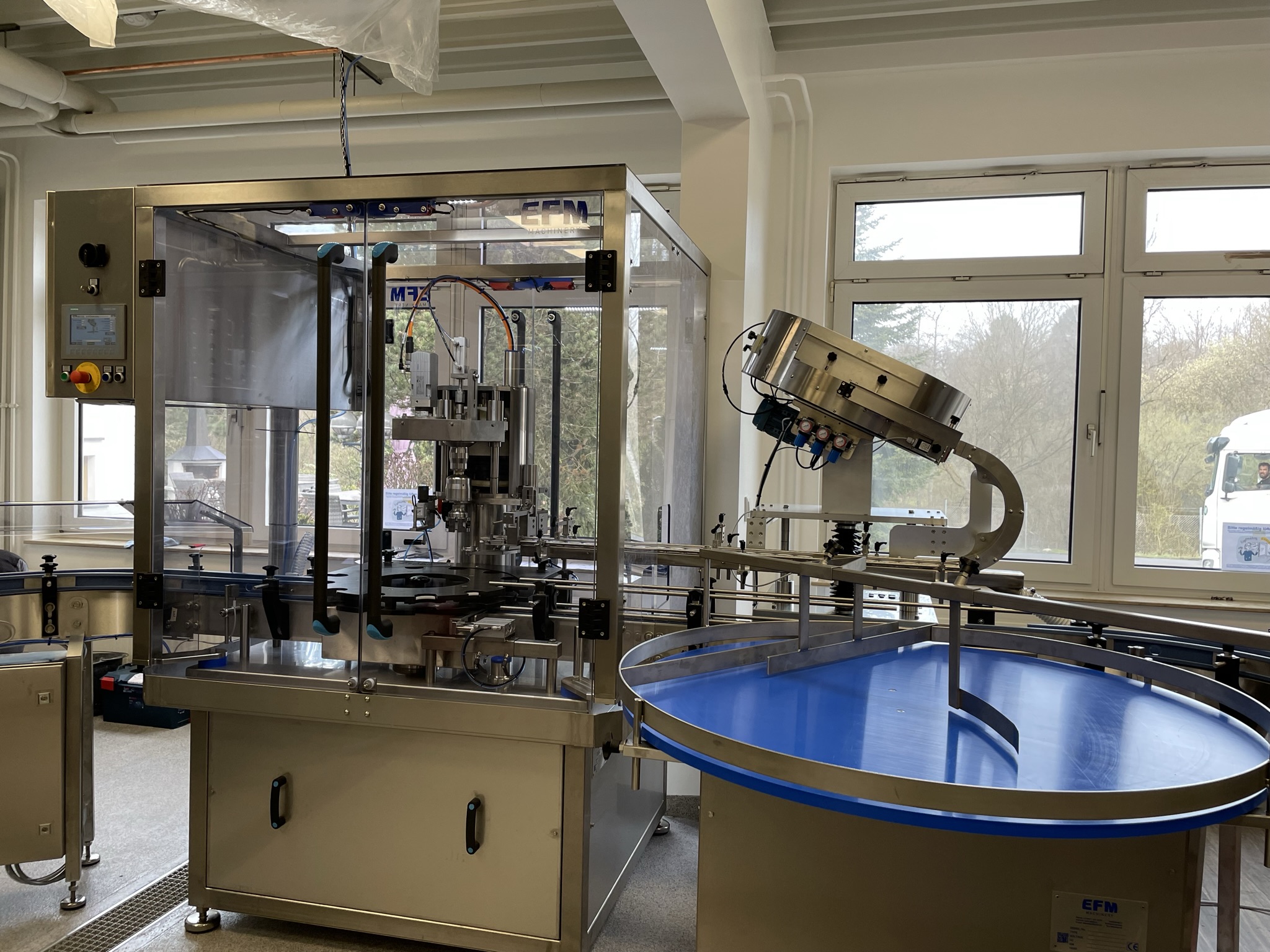

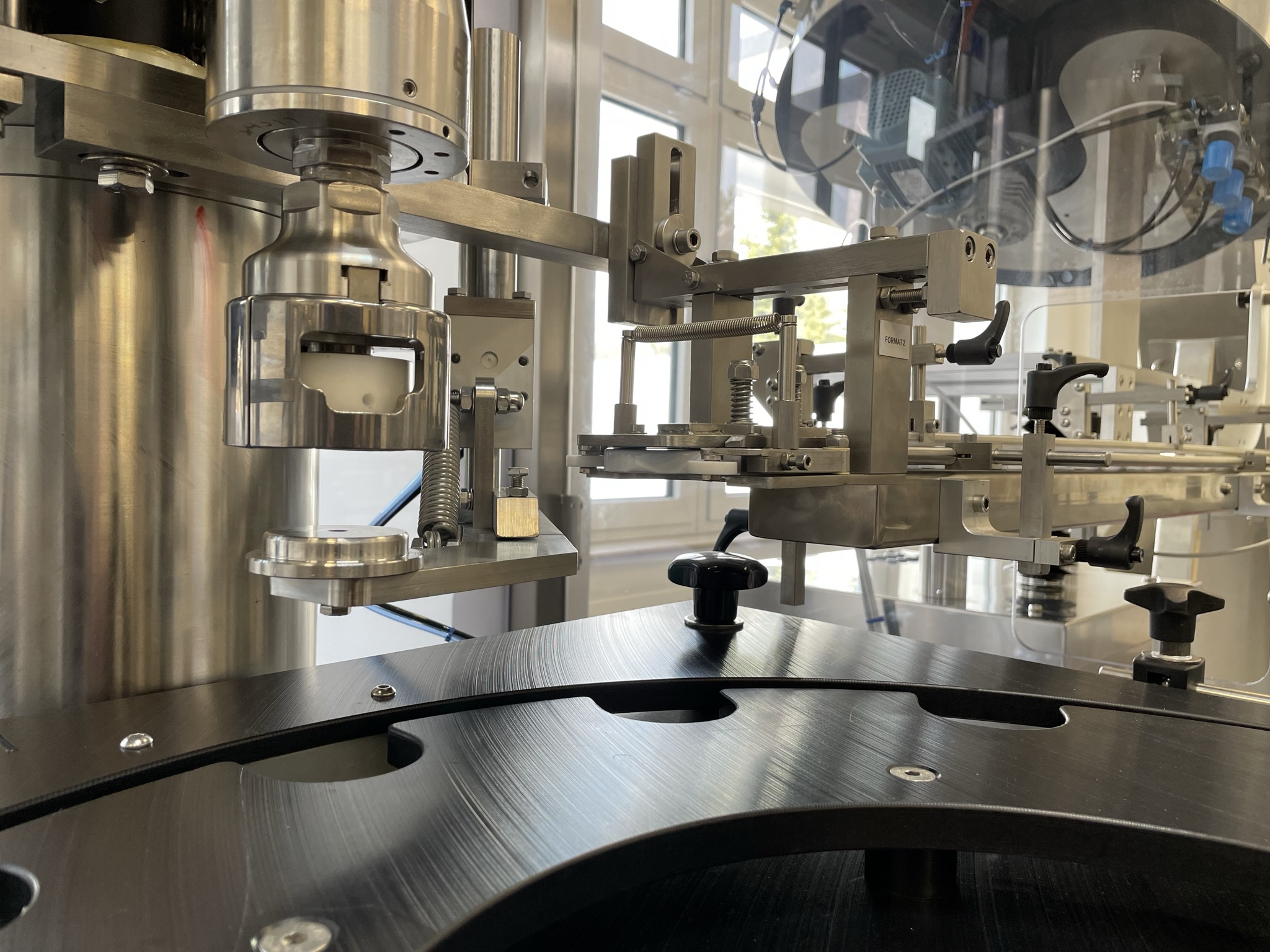

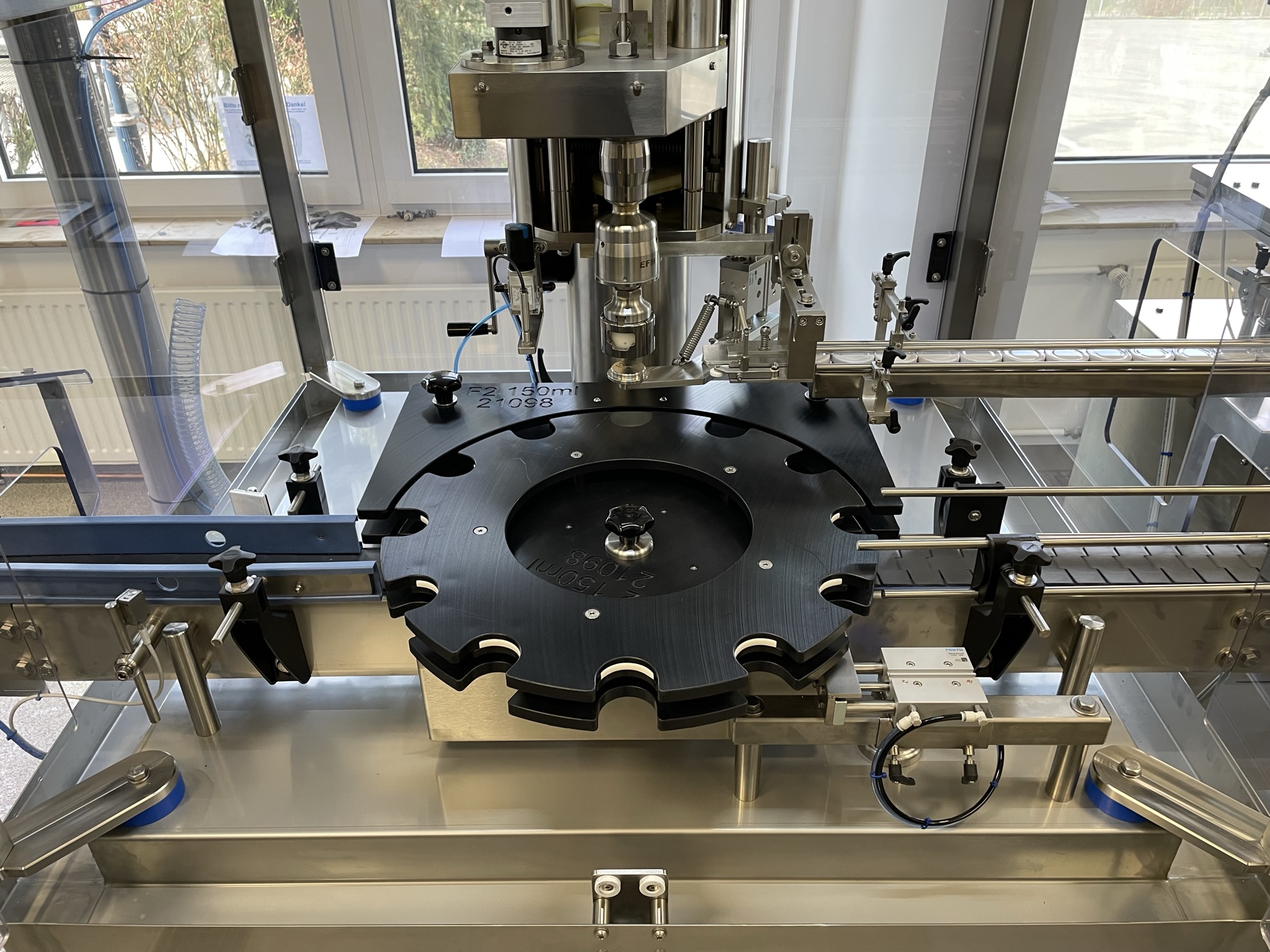

The 1-head ECO1 capping machine handles a wide range of jar sizes as well as different lid sizes, with the lids being automatically supplied from the horizontal cap feed system. After being transferred by the transfer conveyors, the filled and closed jars are given a wraparound label and a closing seal label centred relative to the front label. After this, the packs are collected on our round buffer/loading table and packed manually.

The entire line operates at a maximum capacity of up to 2200bph, and the products are filled at 80°C +.

The machine line consists of:

- Round flat-deck table

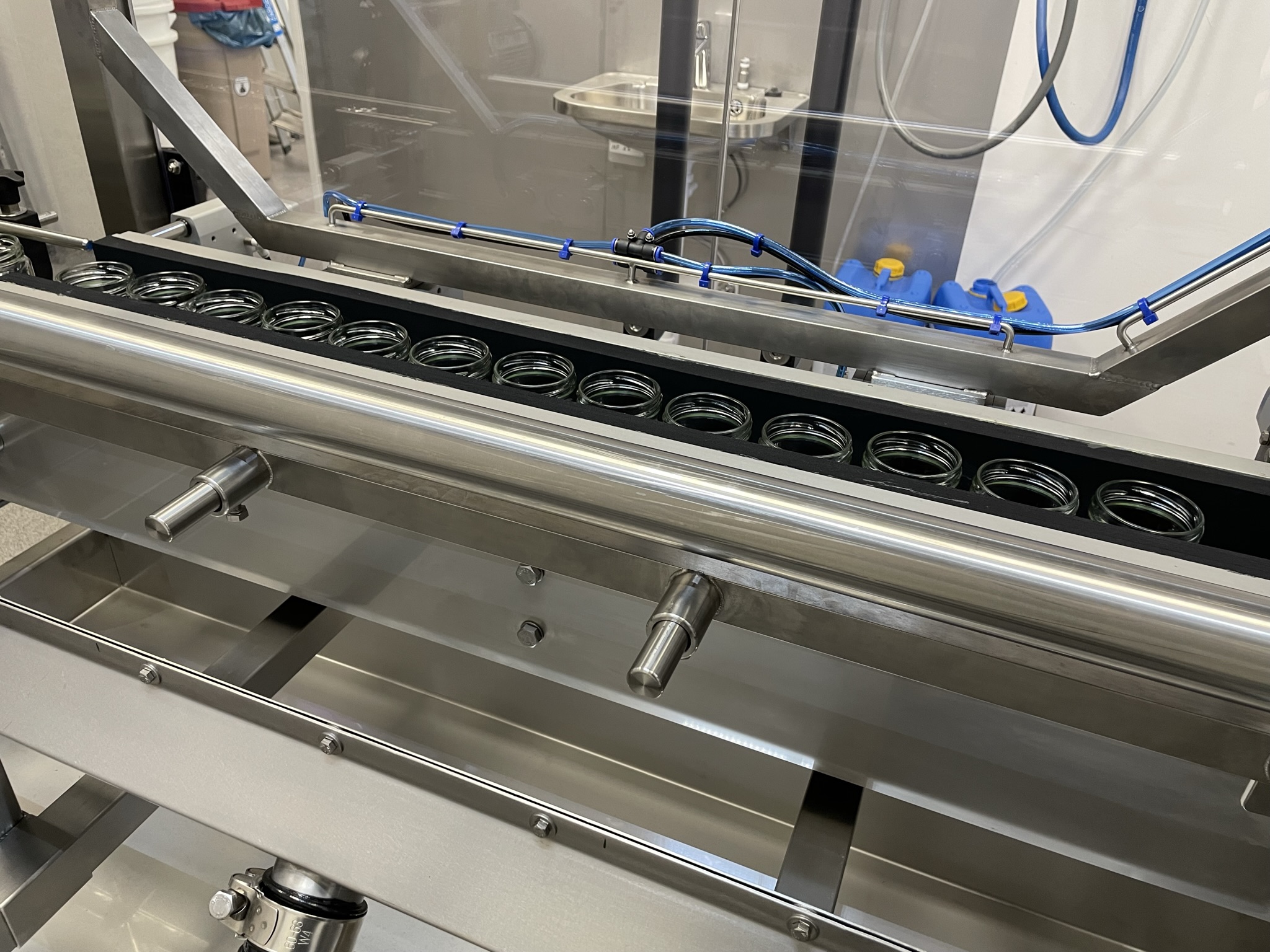

- Inline air blowing rinser

- PS4 (servo-controlled piston) filling machine + tanks + pump and tubing

- ECO1 capping machine with horizontal cap feed

- Wraparound labeling machine with safety label

- Coding

- Round loading table