Compact 2.1 monoblock for swimming pool products

The first general discussion and presentation took place seven years earlier, and production expansion eventually proved necessary in 2019, with delivery early in 2020.

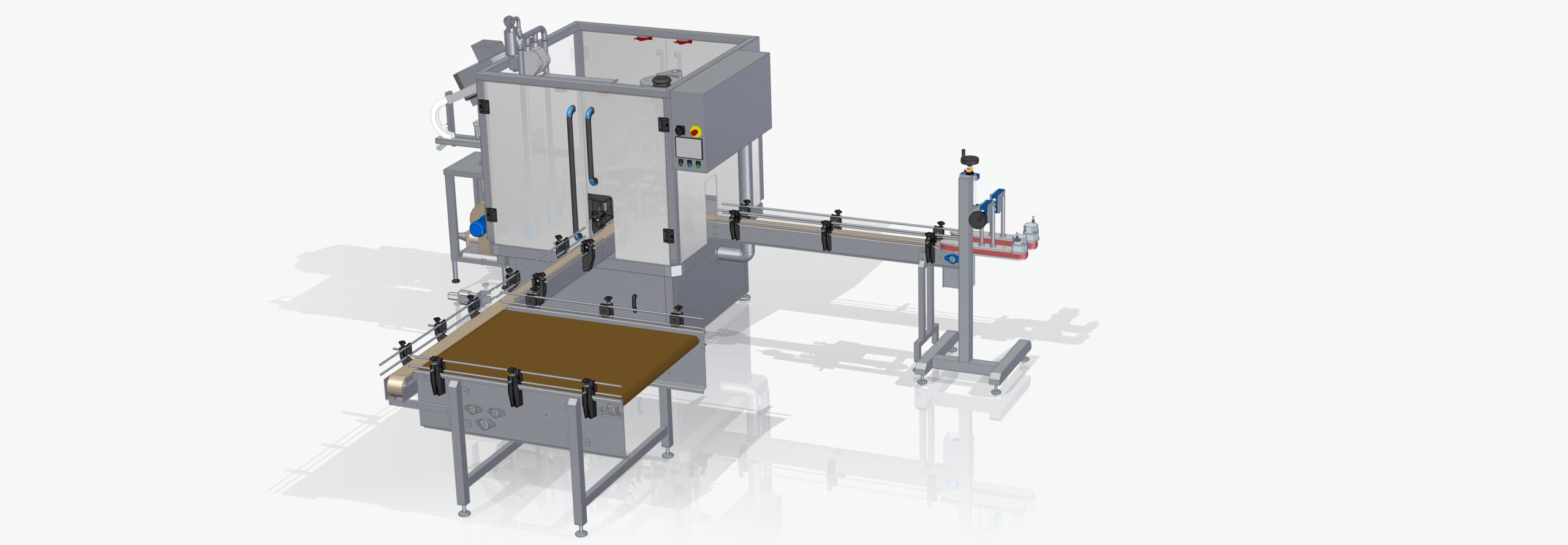

Because of the different sizes, design and volumes of the packaging, an extended infeed conveyor belt is used to provide sufficient buffering.

The empty packaging is processed by the star of the monoblock system, where the packaging is filled by two mass flow meters and the filling section is equipped with a 2.1 collector for a quick and thorough cleaning procedure. All filled bottles are automatically capped with different sizes and types of screw caps, and then transported to the extended discharge conveyor in order to create sufficient buffer to allow one operator to operate the entire system.

Machine line consists of:

- Infeed conveyor belt

- 1 flowmeter monoblock compact machine

- Discharge conveyor belt