Compact 2.1 Monoblock for organic products

At a previous Empack trade fair, we came into contact with this innovative producer of organic cleaning products in Belgium who needed increased production efficiency combined with high flexibility. After a thorough analysis of all applications in combination with products and packaging, the decision was made to supply our compact 2.1 Monoblock, which operates fully automatically on all applications and packaging.

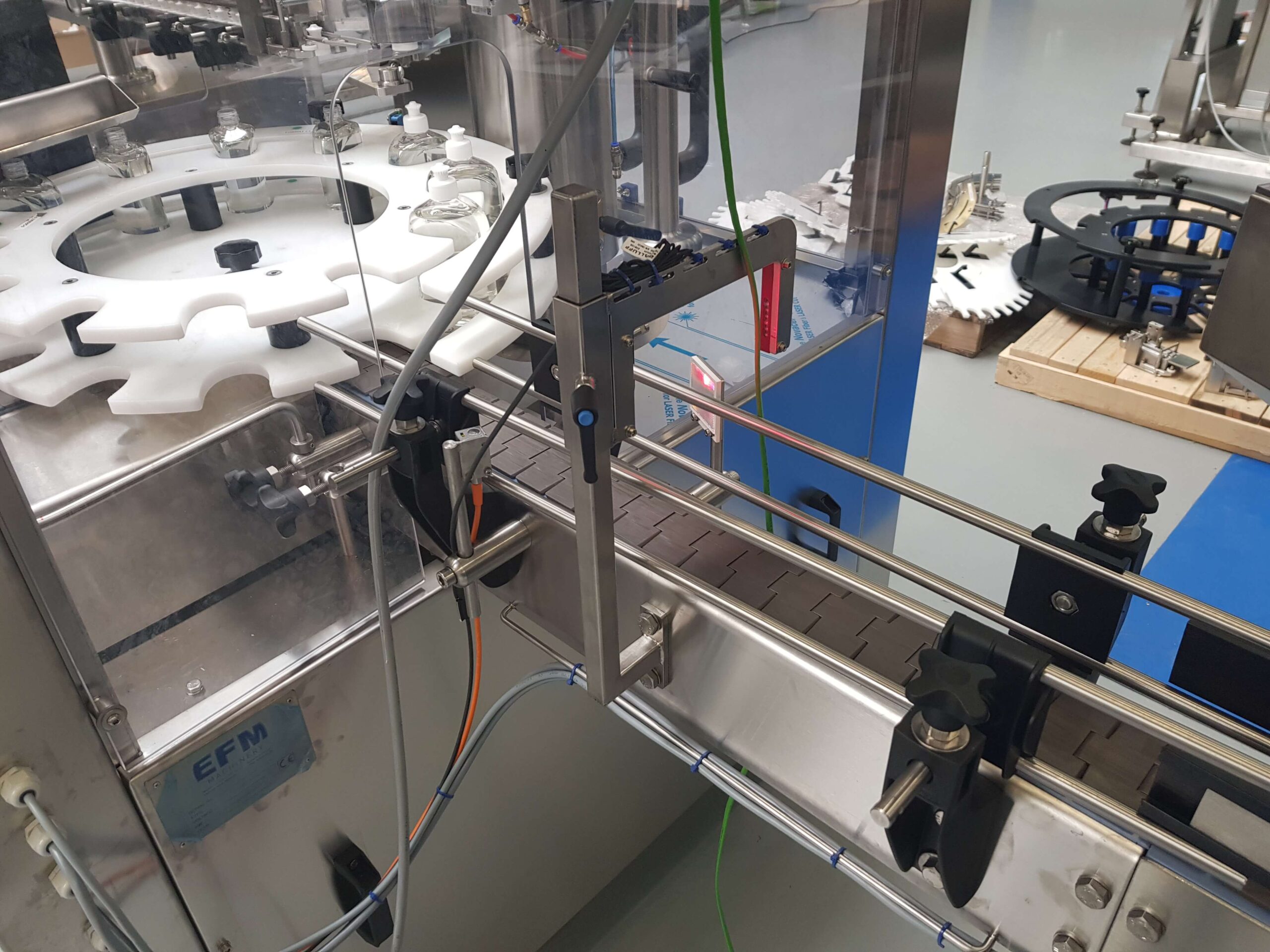

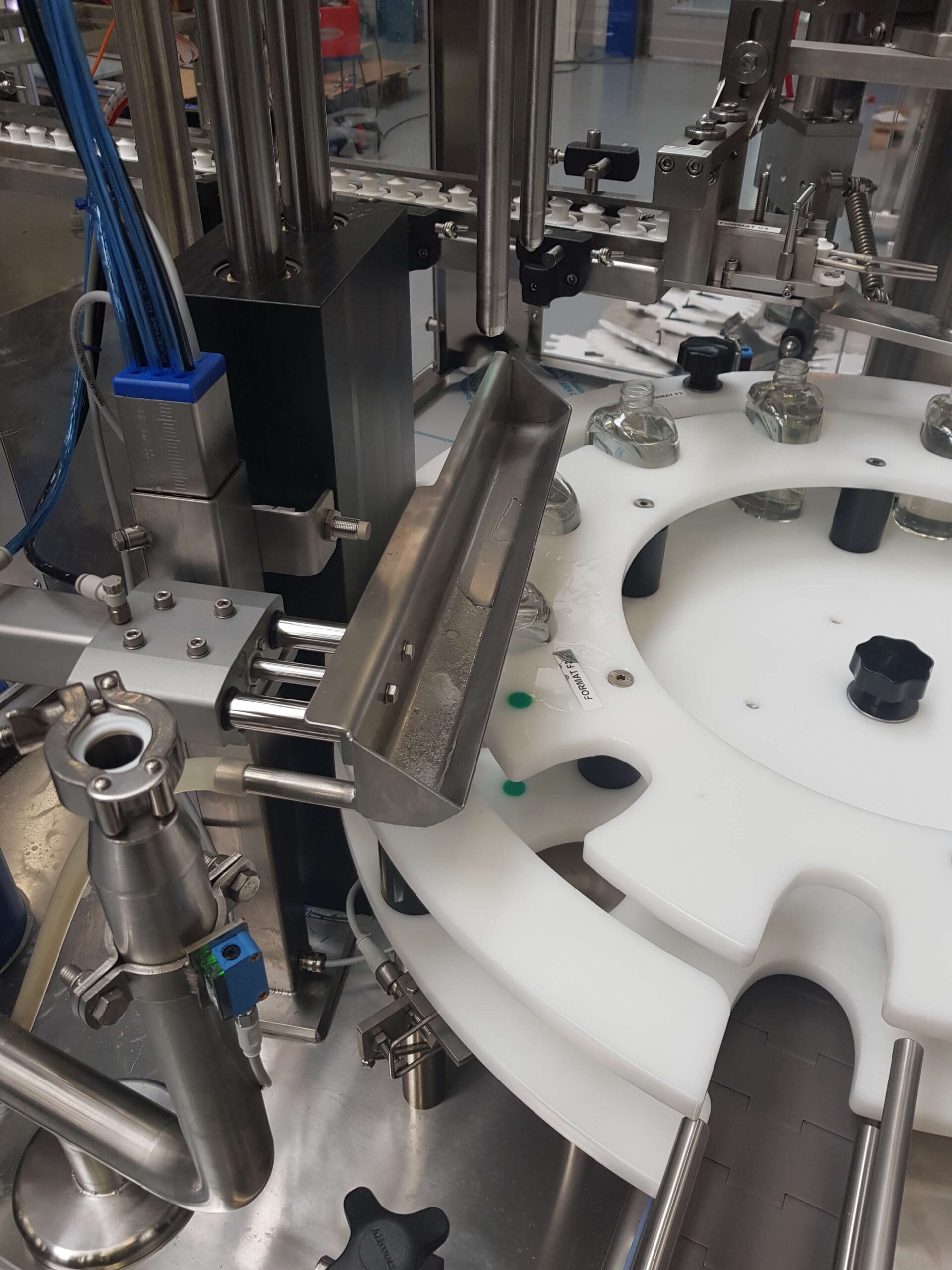

The bottles are manually placed on the infeed conveyor which feeds them into the Monoblock system where they are automatically filled in pairs and capped one by one. Thanks to the servo-controlled filling bridge, the nozzles descend to the bottom of the bottles and follow the filling level during the filling cycle, thus avoiding foaming of the products. By using the stars in the Monoblock, the bottles are always perfectly positioned under the filling nozzles and the capping head, so any adjustments the line operators need to make are reduced to a minimum. The filled and capped bottles continue their way via our parallel transition to the existing labeling machine and on to the round loading table.

This compact filling line was commissioned at the end of March 2019.

Machine line consists of:

- Infeed conveyor

- 1 flow meter Monoblock compact machine

- Discharge conveyor