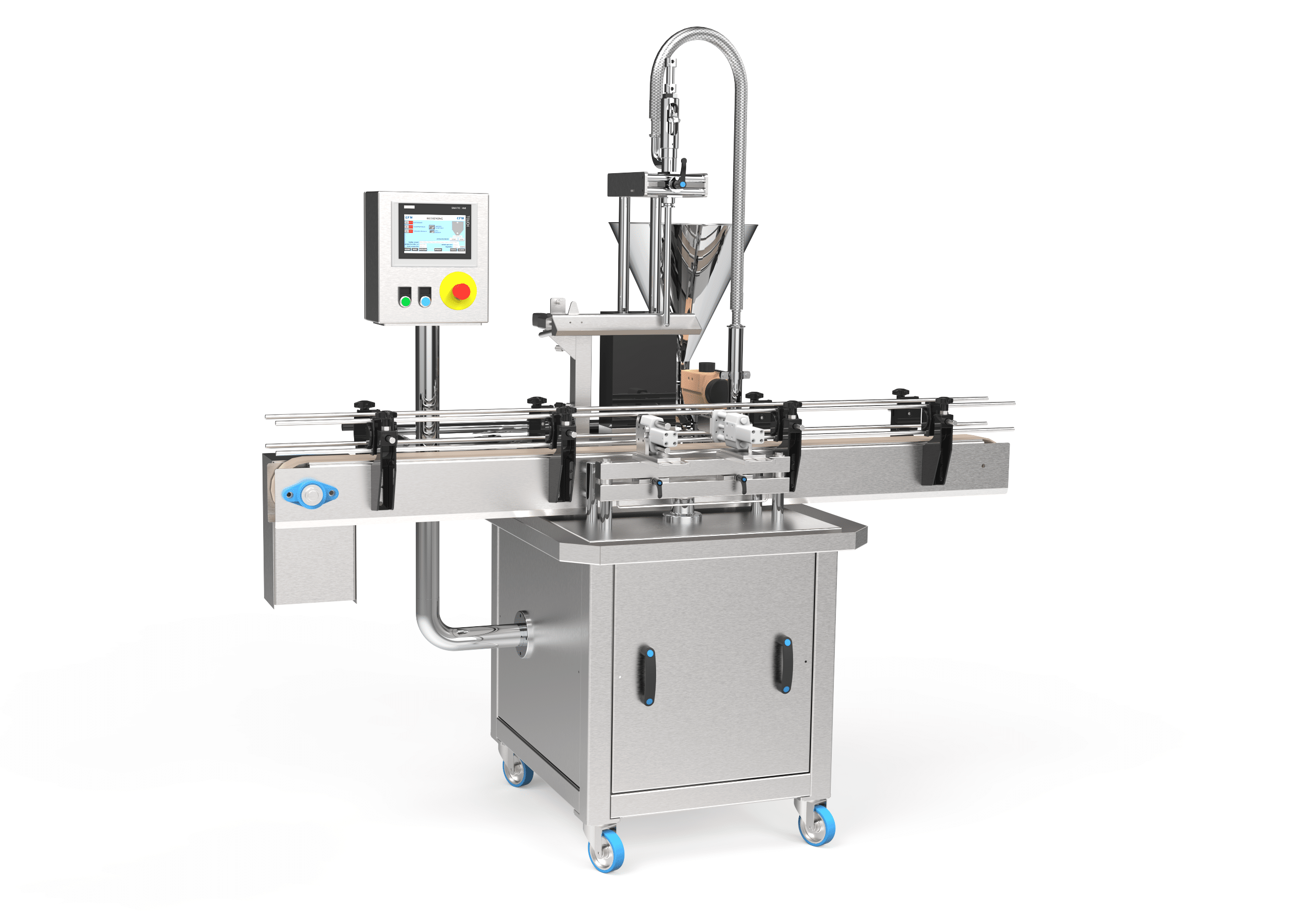

TSA type piston filling machine

This execution of pneumatic filling machine is the next step on our D – en V series filling solutions and are provided with an integrated conveyor for automatic function. Empty bottles are placed directly on the conveyor or optional rotary feeding table. The bottles are separated by means of 2 stopper cilinders. After detection of actual bottle presence b.m.o. 2 sensors the drip tray is placed out position of the filling nozzle(s). The filling nozzle(s) decent into the pot / bottle and the filling cycle is activated. Position to be determend via the touchscreen. After filling the filling nozzle(s) close with positive controle closure and are lifted back into the default position. The drip tray is directly after activated again and goes back into position above the new empty bottle(s). These can be fitted with a single or double piston filler.

Possible versions per capacity depending on volume, size and material tubes

- MTR40/50/70 : 600to4800bph

- MTL100 : 6000bph

- MTL100/2 : 12000bph

- MTL200 : 12000bph

- MTL200/2 : 24000bph

- MTL400 : 24000bph