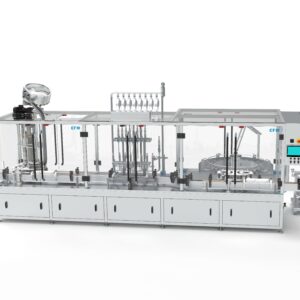

Monoblock compact

The monoblock filling machine is a multi-purpose machine used for various process steps, such as filling and capping jars with lids or pressure caps. The default operation consists of a touch screen from which all functionalities are configured, read out, enabled and stored.

Filling methods

Multiple filling methods can be used. Your selection is made based on the process characteristics, such as the specifications of the liquid, its volume and the type of container. Possibilities include:

- Digital flow meters (Flowrate measurement)

- Piston pump

- Cogwheel flow meter

- Peristaltic pump

- and more.

Sealing methods

For the capping process, you can choose between manually positioning the lids, or use a fully automated cap supply system, using the pick & place system.

For tightening and pressuring you can use:

- Magnetic capping head

- Servo capping head

- Pressured capping head

- Pilverproof capping head

Your Benefits

- Small machine ‘footprint’

- Cost reduction due to combined housing and operation of filling and capping machine

- Short conversion time due to very limited amount of exchangeable parts

Specifications

- Capacity: 600-5000/hour

- Material: Stainless Steel and Synthetics

- Control: Touch screen