Complete and flexible combination filling line 4.1.1. for juices & jams

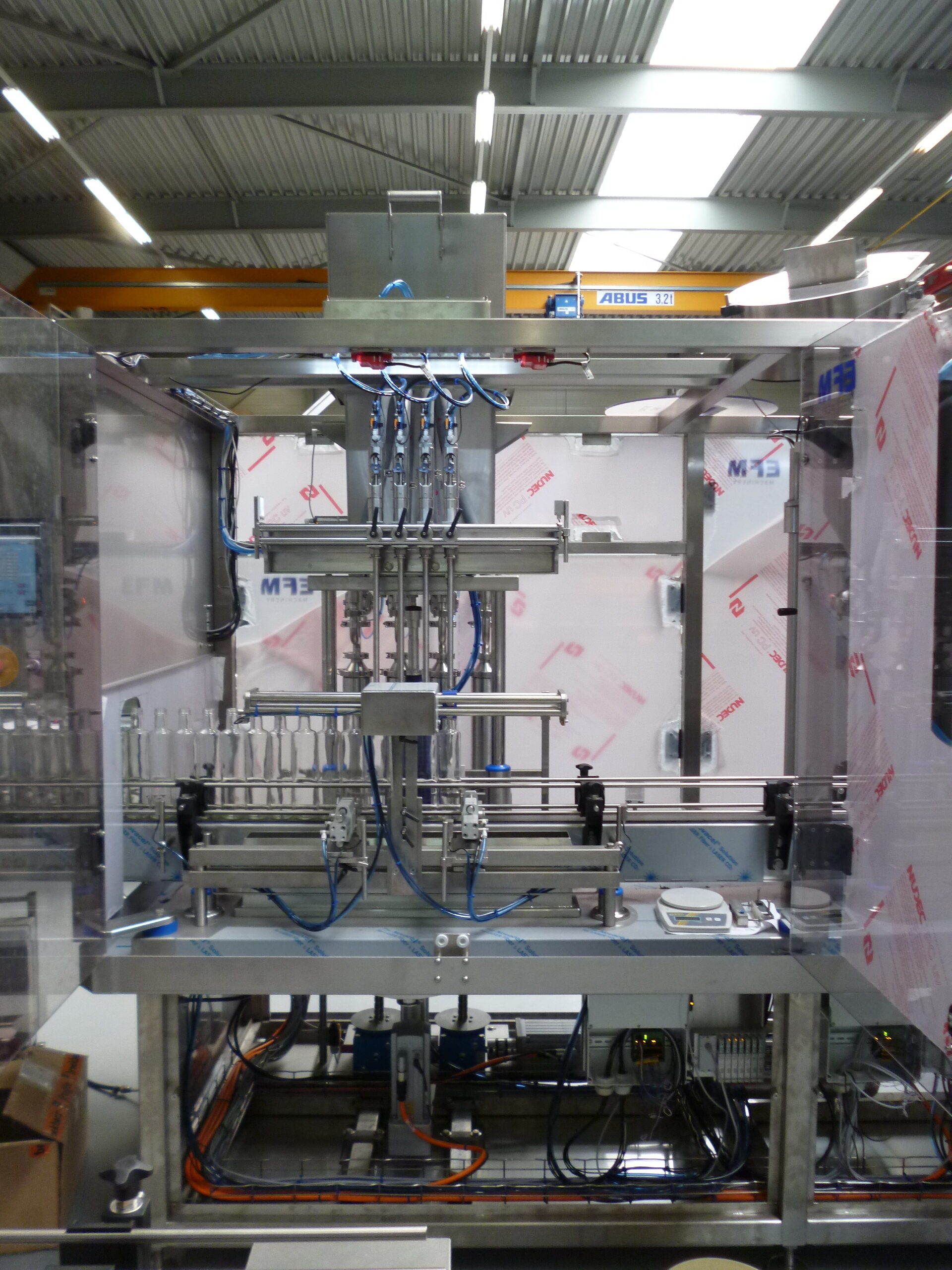

After a period of research into the best possible and most flexible solution, a joint decision was made to opt for a combination filling line, with its very quick and easy changeover between ROPP and twist-off caps.

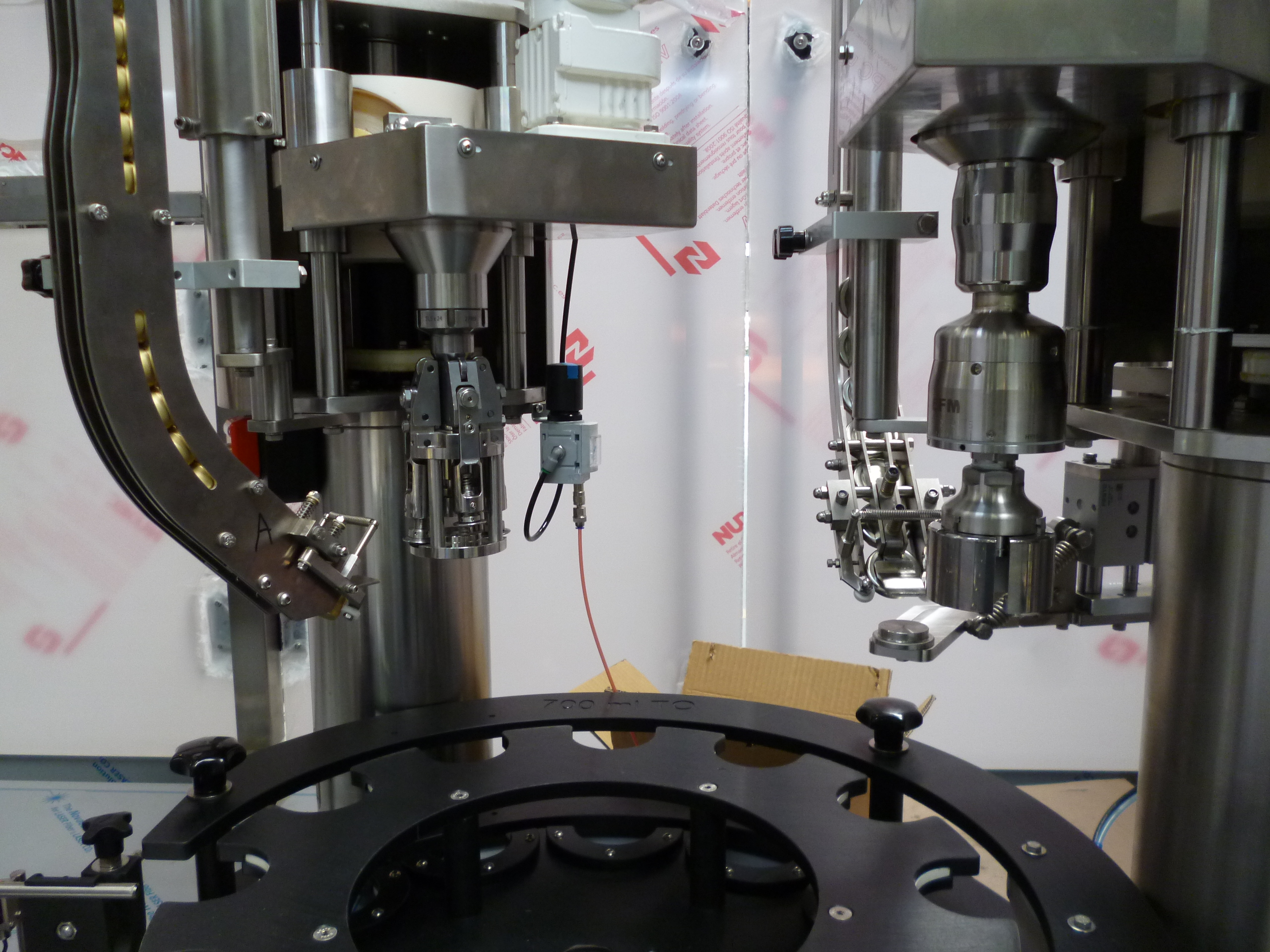

The round glass bottles are placed on the supply table and fed into the 4-head filling section. This is a servo-controlled piston filling principle that lends itself perfectly to these products and applications. After filling, the bottles are moved to the star wheel which has two capping columns. One capping column is equipped to cap ROPP caps, and one caps the twist-off lids. Both capping columns were fitted with their own supply system, supplemented by a cap elevator. During the run, all caps are checked for position and height.

The bottles are then immediately collected by the conveyor belt of the labeling machine, which applies wraparound labels to all the bottles, after which they are coded and collected on the round loading table.

In March 2021, an automatic cartoning machine will be installed which will automate the entire process in various configurations. This MP500 type of packaging machine is equipped with a transit conveyor which can be used for special applications with shorter production runs. This keeps everything very flexible and affordable.

The entire line runs at a maximum capacity of 2000bph.

Machine line consists of:

- Round flat deck table

- 1.1. filling and capping monoblock

- Wraparound labeling machine

- Coding

- Round loading table