Upgrade pail & bucket system on speculose paste.

24/04/2022

A separate devision of the largest producer of speculose paste needed to inscrease productivity and efficiency after the existing filling proces. An already existing semi- automatic filler needed to be expanded with an automatic follow up before palletizing with much less manual labor. .

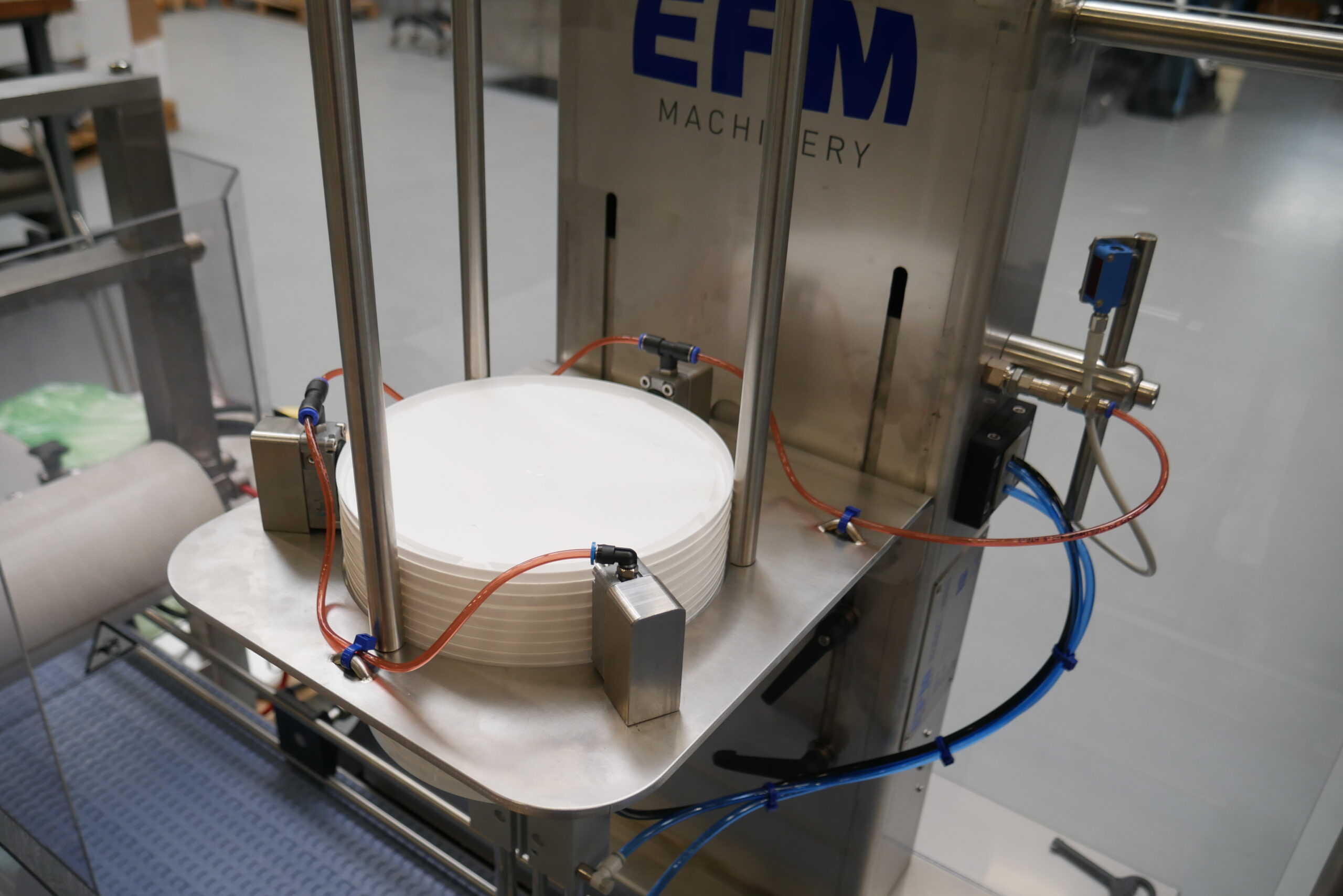

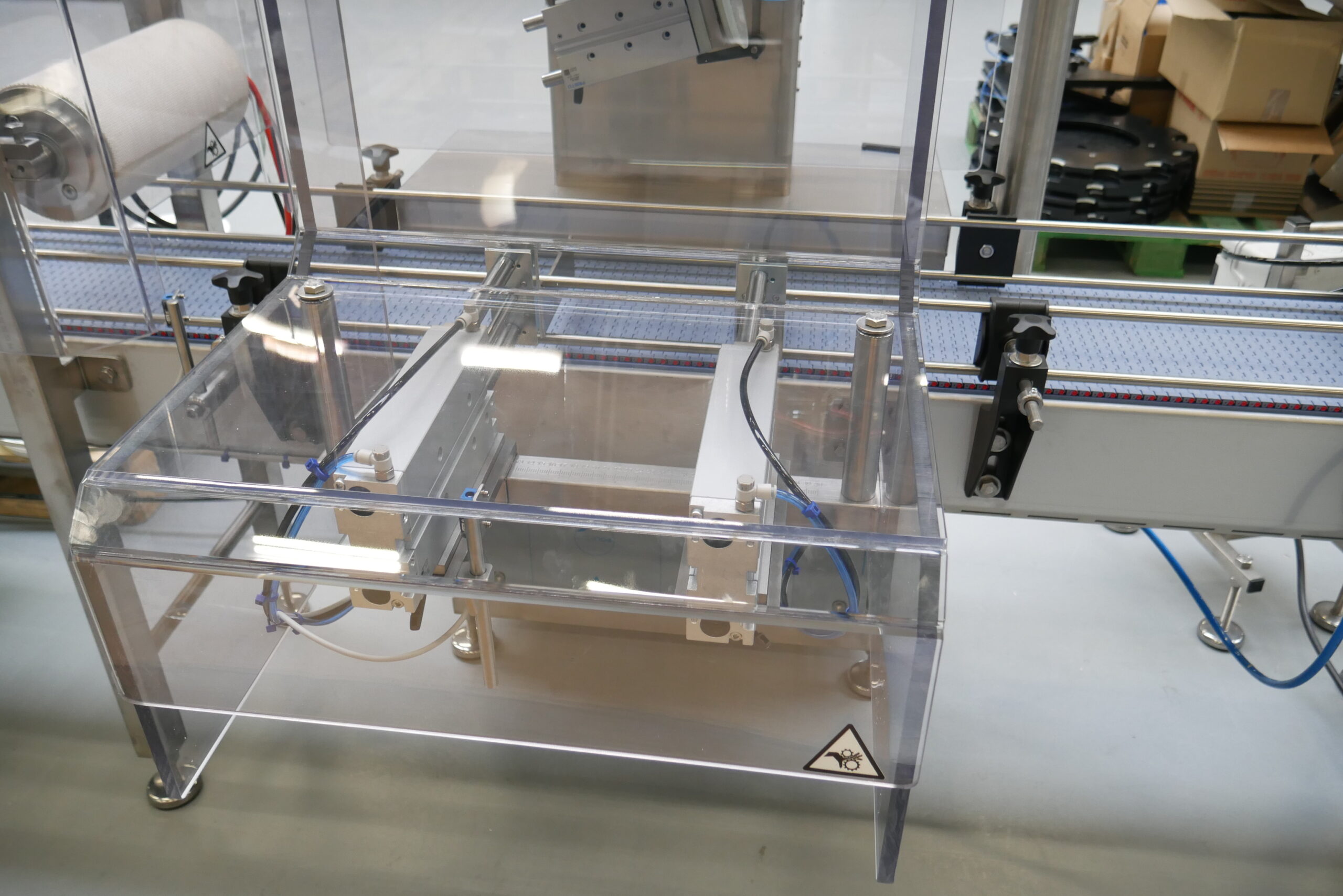

Based on existing installation we provided an automatic lid storage unit that places every lid automatically on de filled buckets and every bucket is positioned before receiving the lid. Directly after placing the lid on every bucket an automatic roller makes sure that every bucket is closed correctly. This for both 3kg and 8kg buckets and therefore is adjustable in height.

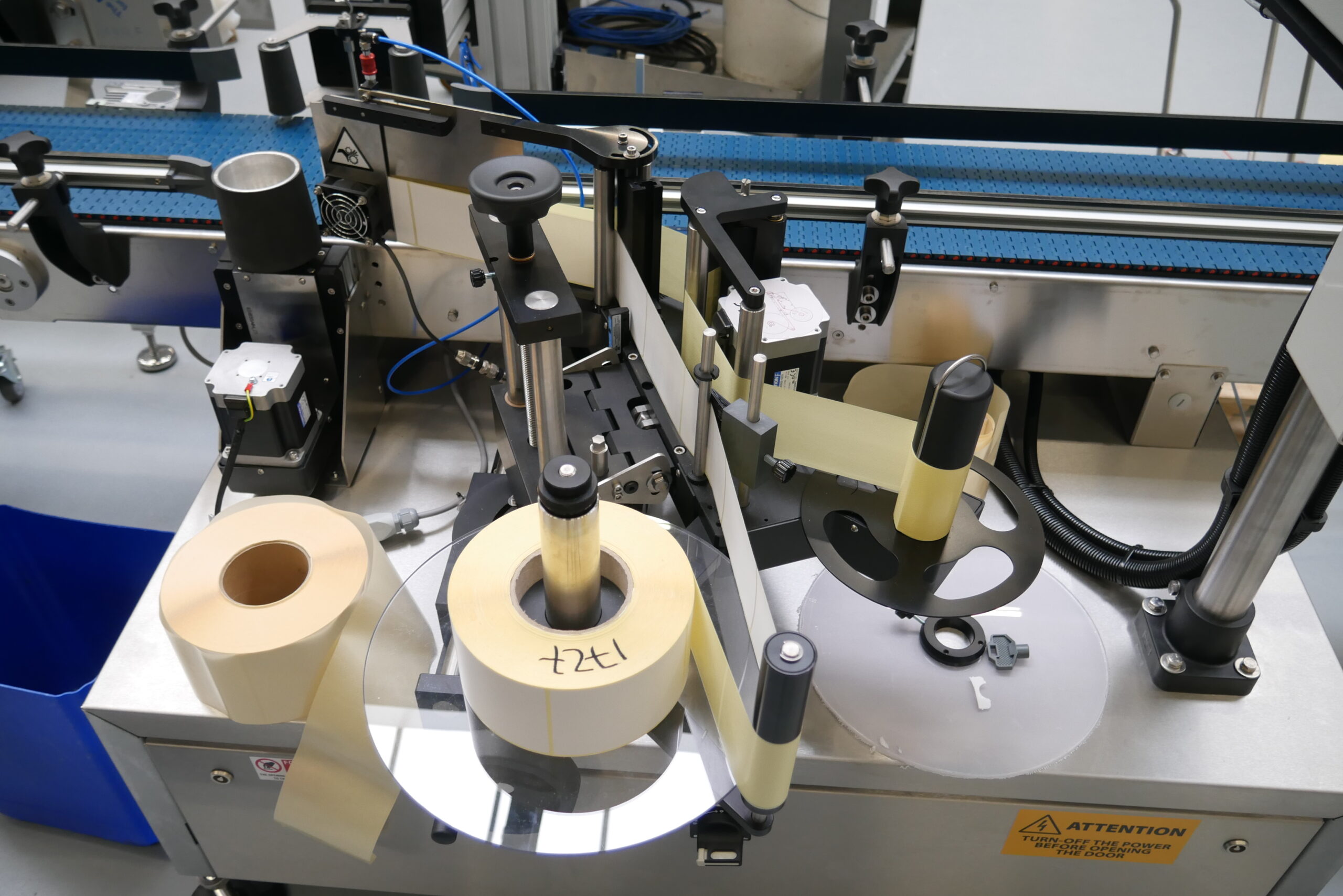

A second conveyor takes the filled and closed buckets over at a higher speed so required space between every bucket is assured which is required for automatic labelling. The labelling system is provided with a 3roller system so every label is centered perfectly between the handle of every bucket. When labelled the buckets continue on a simple free roller conveyor to create the required buffer before palletizing manually.

Machines provided are as follows :

- Lid storage system + placement and continuous pusher roller fitted on a 3M long conveyor.

- 3roller labelling system with separate conveyor.

- Free roller buffer conveyor.