Production innovation optimization for ecological products

After a long familiarisation period and investigating existing production elements in combination with new applications, a number of steps were taken for 3 different production lines.

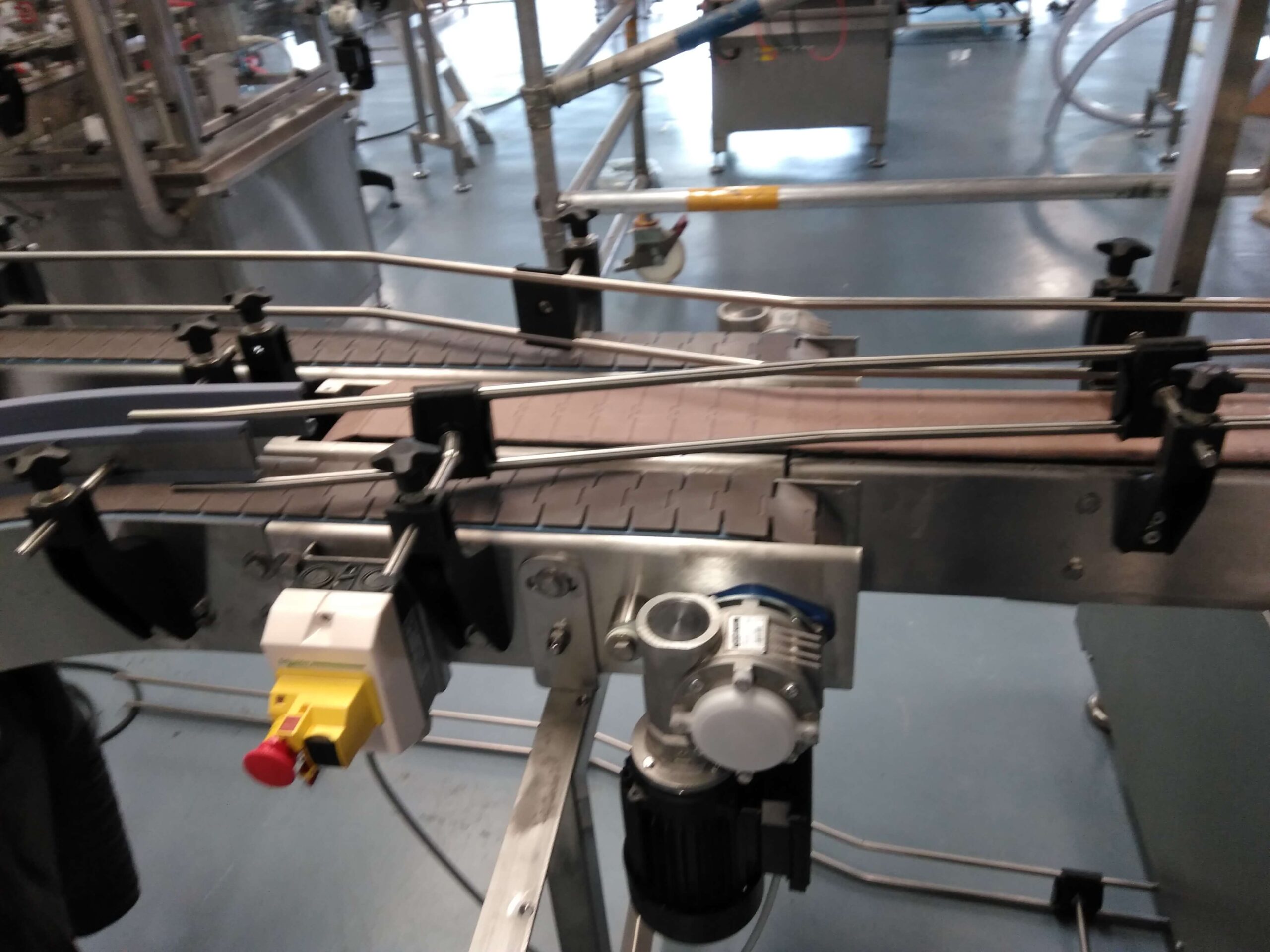

Line 1 for small packaging was composed of a remanufactured 4-header pneumatic piston filling machine and our flexible, semi-automatic and linear trigger capping machine, which can also handle all other pumps and twist-off lids. This line was set up in a double U configuration to integrate with the existing EVOSPRAY capping machine and the existing labeling machine. All required conveyor belts, line controls and transitions were also supplied, and the line operates up to a capacity of 1800bph.

Line 2 for large packaging was a simple exercise for setting up the existing filling and capping machine as a U-filling line. For this, only 2 additional curve conveyor sections were needed for the required transitions.

Line 3 was a separate rotating tube production system, fitted with a tube stock area for empty tubes + automatic feed into the carousel pucks. The tubes were then automatically positioned, filled, folded, sealed + coded and cut before being automatically removed from the carousel.

These different filling lines were commissioned by the beginning of September 2019.

Machine line consists of:

- Custom-made conveyor belts + connections and parallel transfers and controls.

- 4-header pneumatic filling machine

- Capline H/A trigger capping machine

- Rotating Tubeline system