Honey filling lines

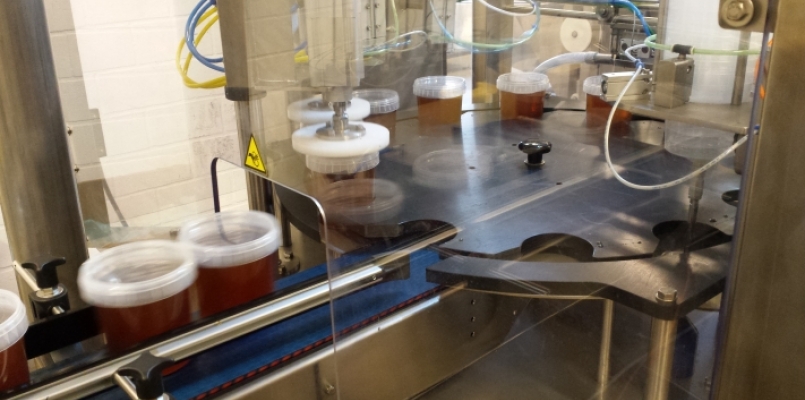

Compact filling line for honey in pots:

A rapidly growing company specializing in everything revolving around bees and honey invested in two simultaneous filling lines. The first line consists of a monoblock 2.2 system equipped with a double pot unstacking system, full integration of a double existing filling machine and a double lid unstacking and pot closing system. These conical pots are then put onto a discharge conveyor equipped with a one-sided labeling machine after which the pots are collected on the buffer table.

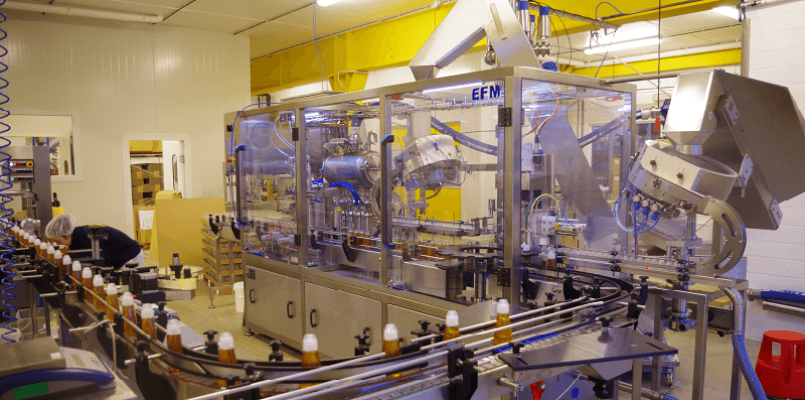

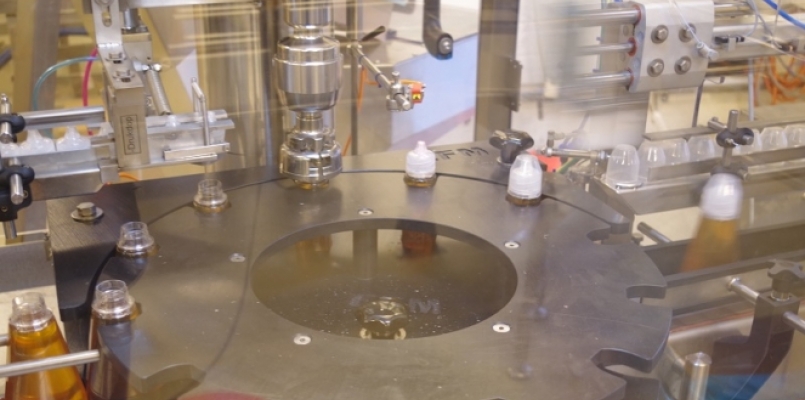

Complete filling line for honey in bottles:

In addition to the existing production facilities, a brand-new filling line was installed to process another form of packing: glass oval bottles, and two sizes of PET oval bottles. The glass bottles are filled with a four-headed servo-controlled piston filling system integrated in a Monoblock 4.2, after which they are transferred by an existing conveyor leading to an existing sealing and labeling machine. To maintain a large degree of flexibility, all other bottles are both filled and sealed in the Monoblock system. The glass bottles are sealed with a screw cap and the PET bottles are sealed with two caps. This configuration, equipped with one piston and one element to put the caps in place, offers an hourly 2,200 bottle capacity. To further reduce ‘down-time’ to an absolute minimum, a second simple labeling machine was installed for all wrap-around appliances.