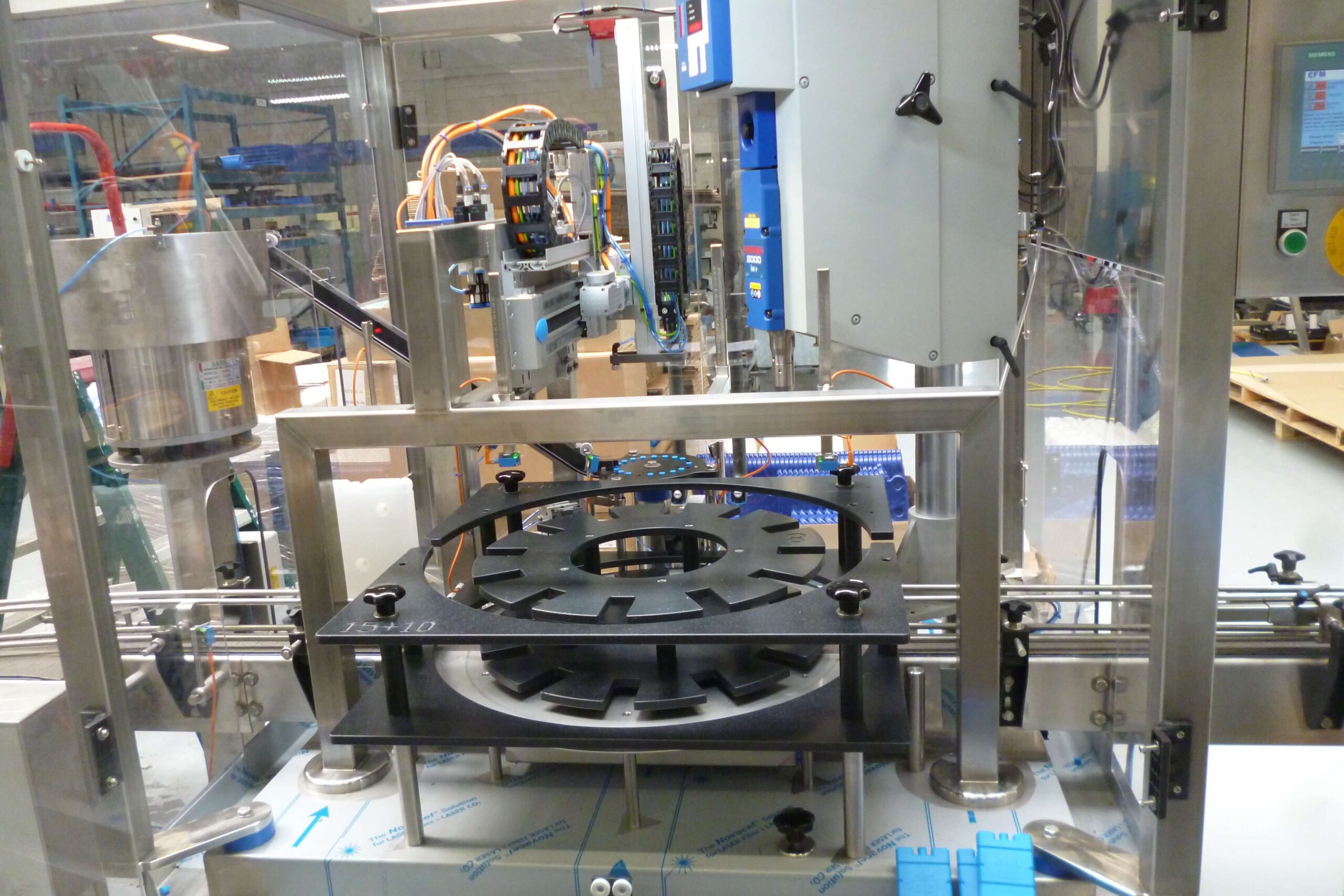

Filling line for cooling elements fitted with special ultrasonic capping machine

A standard filling line for processing COOL ELEMENTS does not exist, so we needed to develop an extremely flexible filling line for processing approximately 20 formats of between 90ml and 1500ml with a nominal capacity of 4000bph.

Our 6-header servo-controlled piston filling machine is the only standard machine in this line, and is equipped with some specific options. However, separating and positioning the insert caps, ultrasonic capping and the discharge buffer, are all very specialised developments. An excellent challenge for our design engineers.

After filling, the cooling elements are transported directly to the capping machine, and are then transported and positioned in the star of the capping machine. The insert caps are sorted using a vibrating bowl, and arranged in a double line in the specially developed pick & place system, which lifts the caps by vacuum and places them in the cooling elements while applying light pressure to the sides of the cooling elements to allow any excess air to escape. An integrated ultrasonic unit was built (instead of a standard capping column) to ensure that the caps are “fused” with the cooling elements to provide a perfect hermetic cap.

The special infeed conveyor ensures that the cooling elements are correctly fed to the filling machine one by one. The specially developed discharge buffer conveyor works in the same way, after which the packaging into cardboard boxes is done manually.

This filling line was commissioned in the second half of April 2018.

Machine line consists of:

- Linear supply conveyor

- PS6 filling machine

- Special ECO1 capping machine with ultrasonic cap

- Linear discharge buffer conveyor