Complete 10,000bph filling line for hand gels

12/03/2021

Due to the huge increase in demand for hand gels and disinfectants since March 2020, our Dutch customer decided to invest in a complete filling line. This was for processing small packaging, i.e. round and oval PET bottles closed with flip-open caps and pumps. Their contracts increased to such an extent that it was decided to build a complete line with a capacity of 10,000 bph.

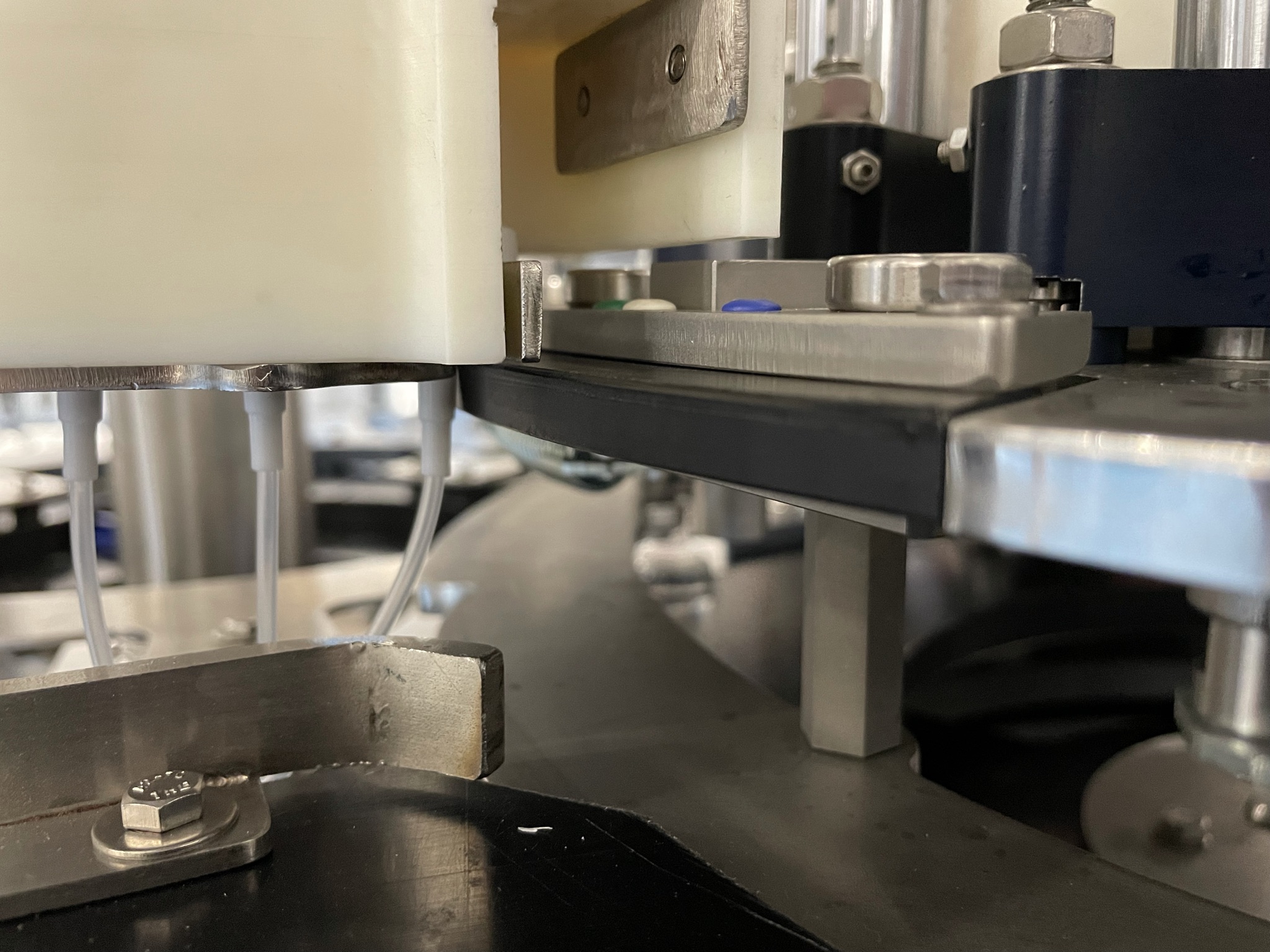

The solution was to install a bottle unscrambler SB10000 which feeds the bottles via a vacuum conveyor to the PS16 filling machine. After the bottles are filled, they are transported to a fully automatic capping machine which adds the pumps and other types of screw caps. This special capping machine was developed and built by our partner Rejves.

After closing, all packs are checked by a special check weigher, and then transferred to the rotary non-stop labelling machine. A coding unit was also integrated into one of the labelling heads.

Final processing consisted of 2 parts, one of which was our standard MP1000 cartoning machine, which automatically packs most packages into American folding boxes. The MP1000 is also fitted with a transit conveyor, which is able to seamlessly feed the other packages for manual packing.

The machine line consists of:

- SB10000 unscrambler with vacuum conveyor

- PS16 servo-controlled piston filling machine

- Rotary capping machine for pumps

- Special check weigher

- Rotating non-stop labelling machine with servo platforms

- MP1000 cartoning machine for American folding boxes and transit lane

- All necessary conveyors in U-arrangement and equipped with separate line controls