Automatic flowmeter filling line for liquid plant food

10/04/2021

For this Belgian market leader in fertilisers and plant food, an investment in a new filling line was needed to cope with the increased capacity, to process the new design bottles and to increase overall flexibility.

The new line was fitted with a rectangular flat-deck table from which the empty rectangular bottles (50ml to 1000ml) are fed to the 5-head Magg flowmeter filling machine, which is equipped with a 5.1 collector for a quick and easy cleaning process, as well as a bottle counter and V-centering. In order to also handle smaller volumes efficiently, a second set of smaller diameter filling nozzles was provided, so that product flow could always be perfectly controlled.

After filling, the bottles are fed into the star of the ECO1 capping machine, where the differently sized bottles are closed by 1 type of screw cap. A second automatic capping machine takes care of sorting and fitting the dosing caps on top of the screw cap.

These bottles are further provided with 2 L-type corner labels, the transition is achieved seamlessly using a transfer conveyor. The bottles are transported under the induction sealing unit and collected by the round buffer table. The line was built in a U-configuration so that one operator has a complete overview.

The filling line operates at a maximum capacity of 2200bph.

The machine line consists of:

- Rectangular supply table

- 5-head Magg flowmeter filling machine

- ECO1 capping machine for screw caps

- Capping machine for sorting and applying dosing cap on top of screw cap

- ZB34-600 transfer conveyor

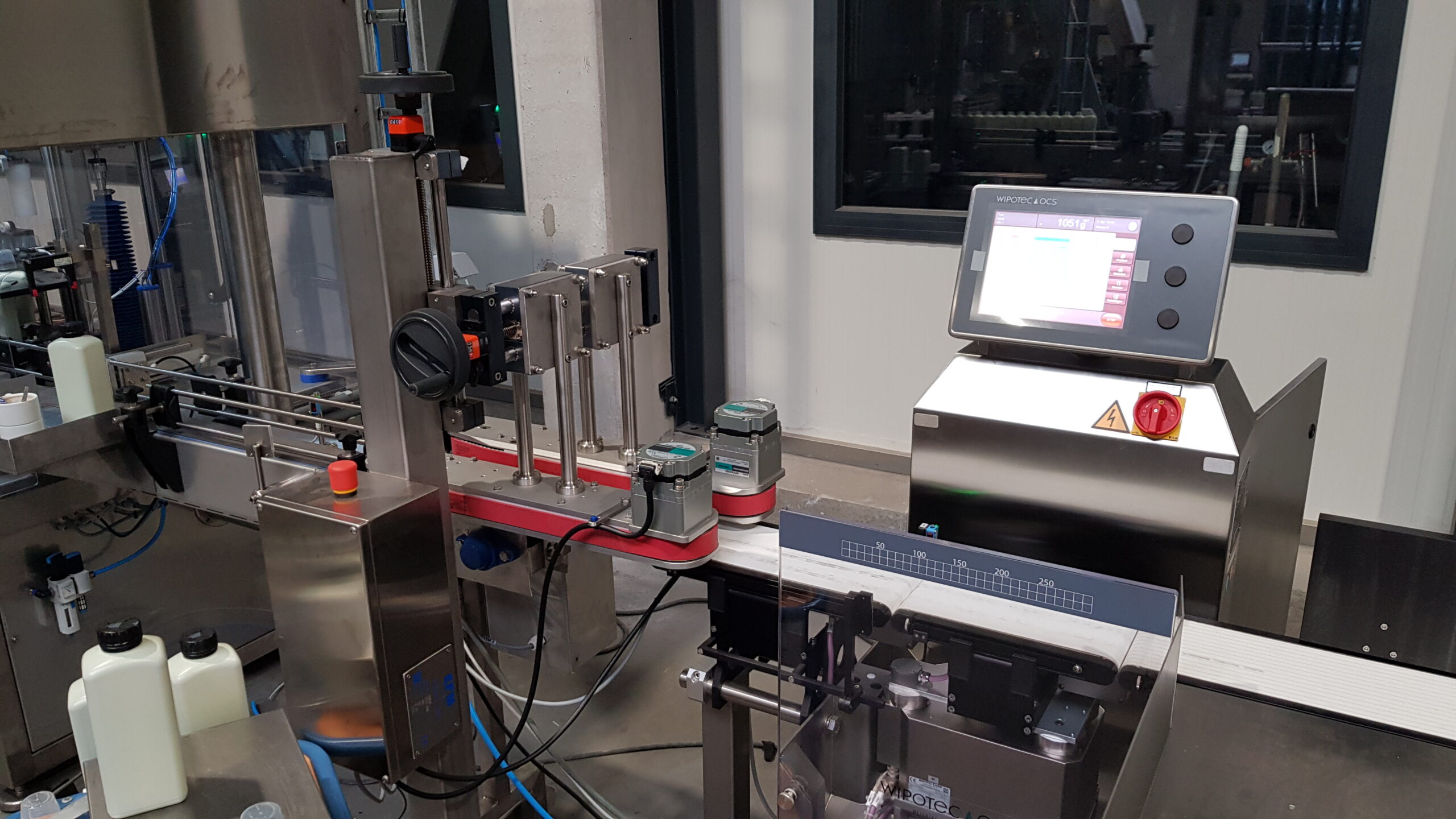

- Integration of existing labelling machine

- 2kw induction sealer

- Round collection table